Injection Mold Manufacturing

Nhait is a renowned producer of injection moulds, focusing on creating excellent quality moulds for various sectors. Accuracy and ingenuity are delivered to fulfil the needs of multiple clients.

Injection Mould Manufacturing Process

WHAT WE DO

01

Design

Here, you produce 3D models and technical drawings.

02

Selection of material

You have to choose a suitable plastic resin for the mould. Choosing the right materials is an essential aspect as this would have effects on the final products.

03

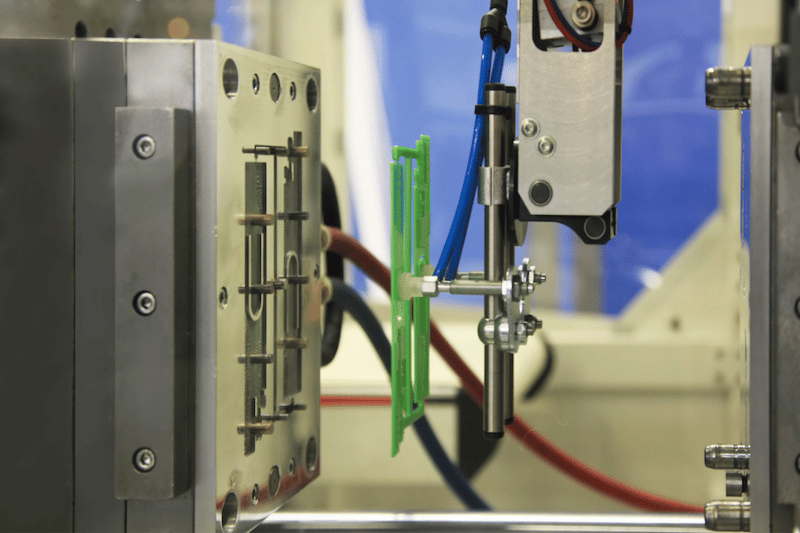

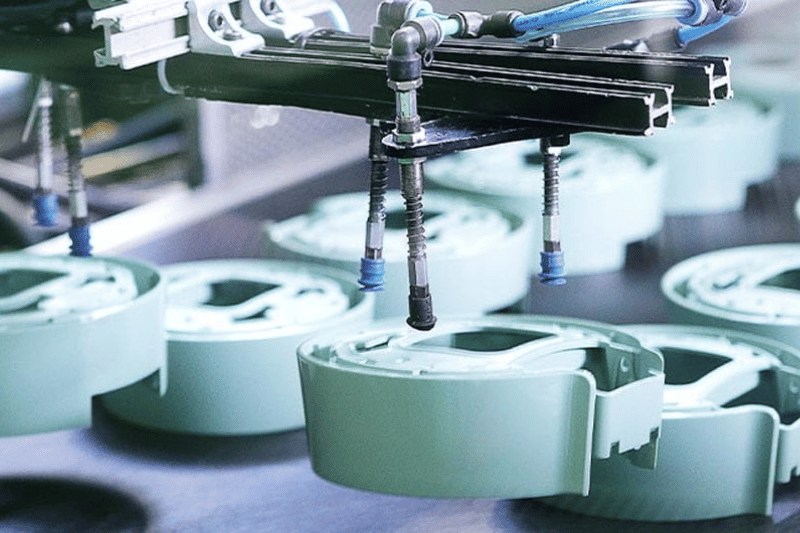

Injection

The plastic resin is heated and injected into the mould.

04

Solidification and removal

This step enables the molten plastic to set up inside the mould. Ejection is the process of removing a hardened component from a mould cavity.

05

Finishing

Any excess materials are trimmed off and the product has a smooth surface finish.

06

Shipping

All products that have passed the quality checks will be packaged and distributed to clients worldwide.

24/7 Towing Service

24/7 Assistance

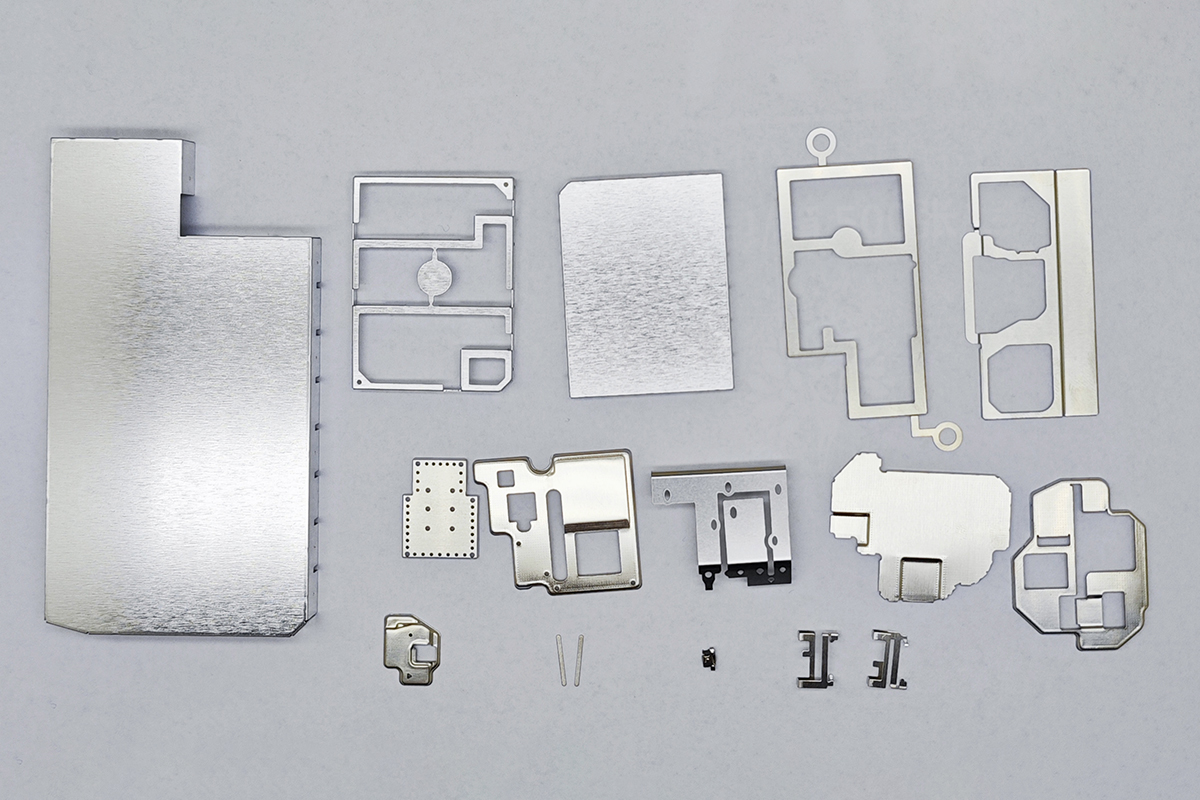

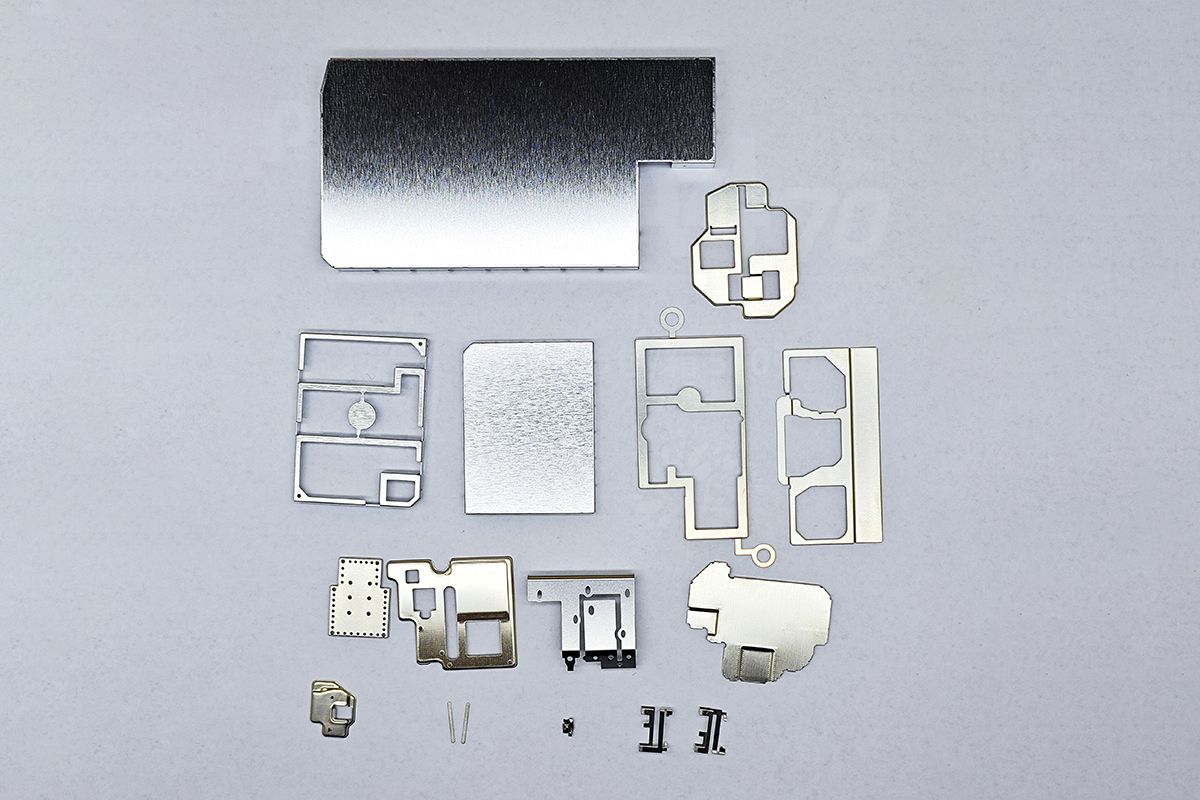

Custom Injection Mould Parts Solutions

WHO WE ARE

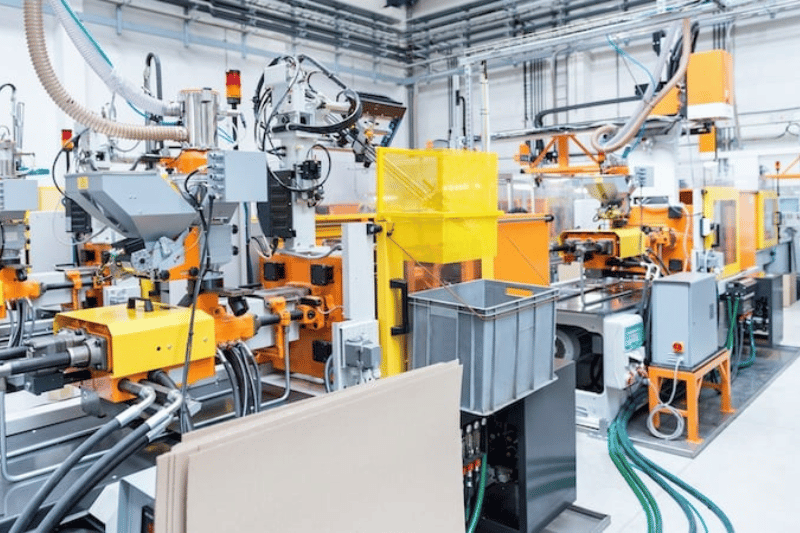

Introducing our solution for custom injection-moulded parts: We specialise in providing specialised and superior injection-moulded components to satisfy the various requirements of our customers. We guarantee accurate design, effective production, and prompt delivery with a committed team of professionals and cutting-edge manufacturing facilities. We offer a complete answer to all of your injection moulding services.

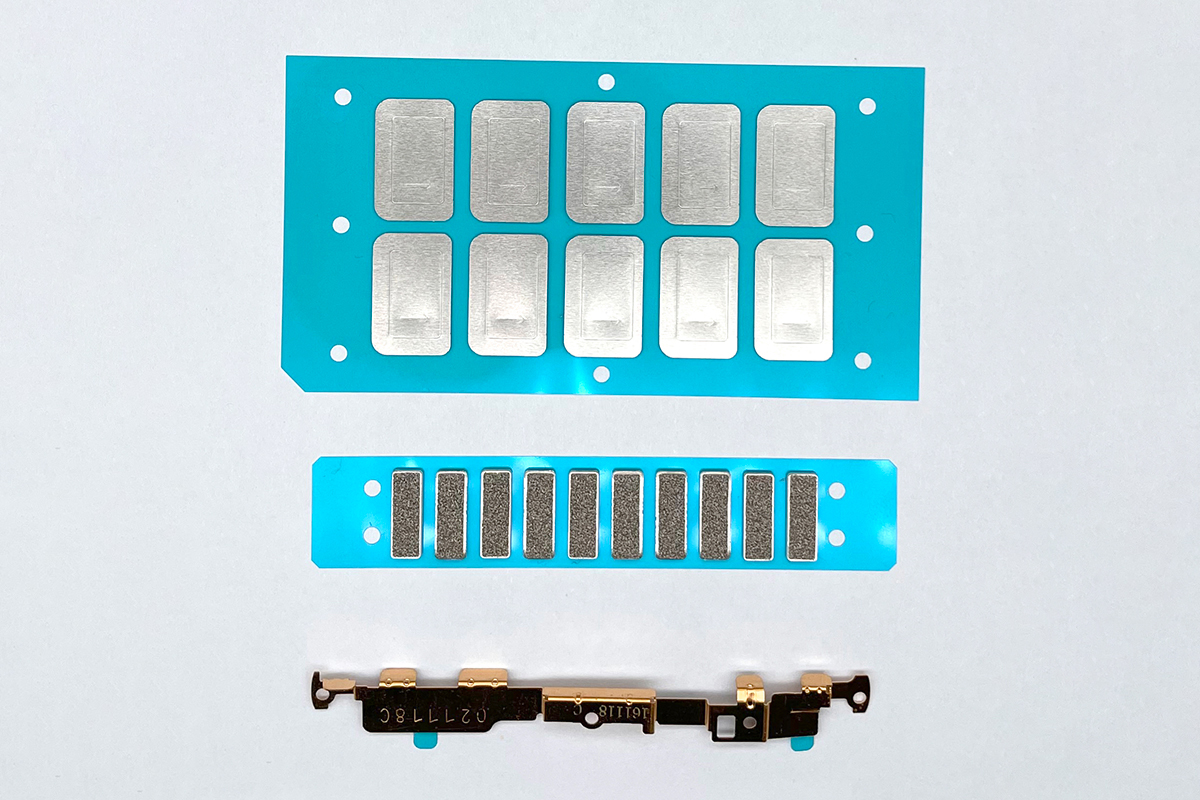

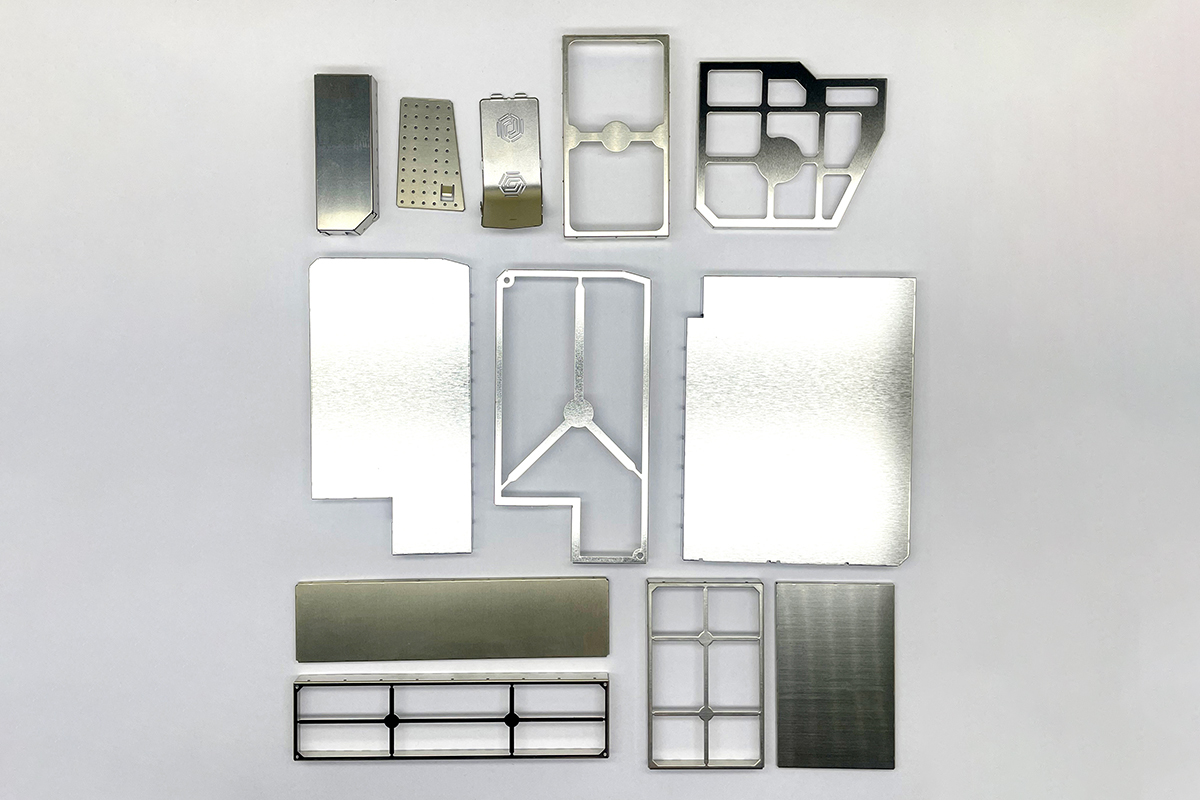

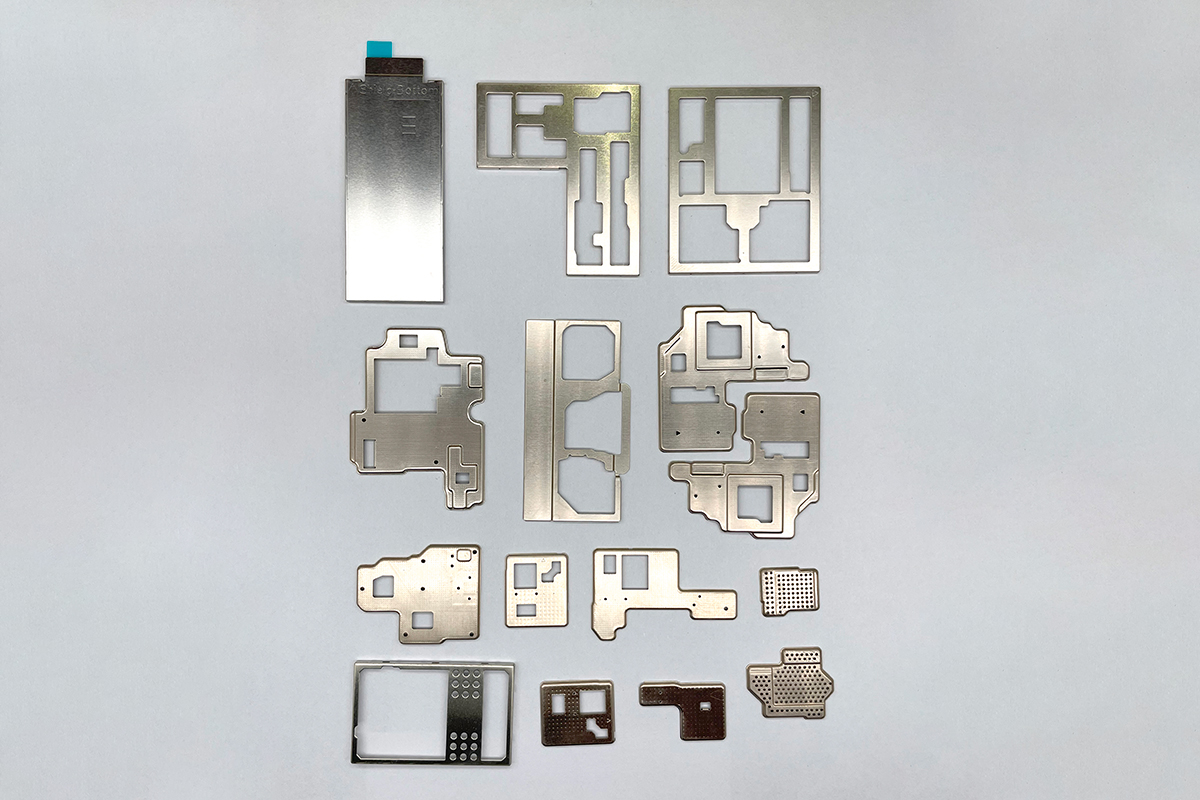

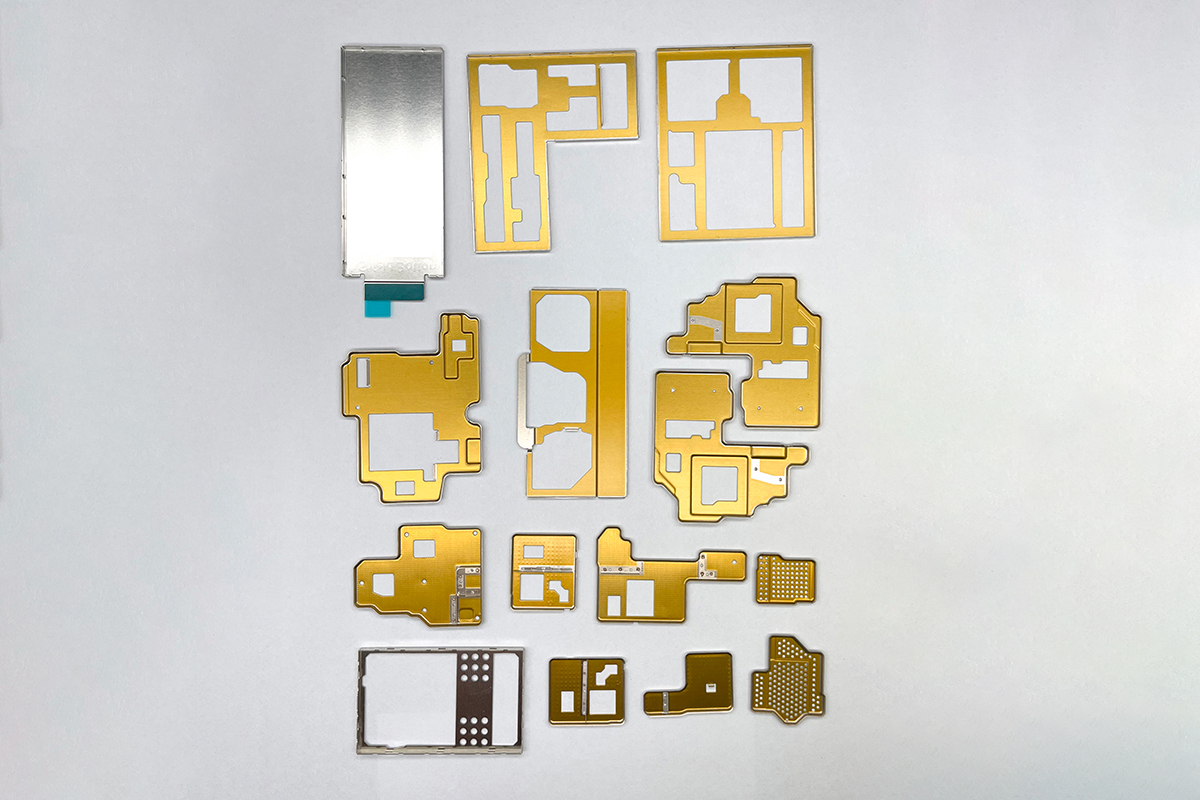

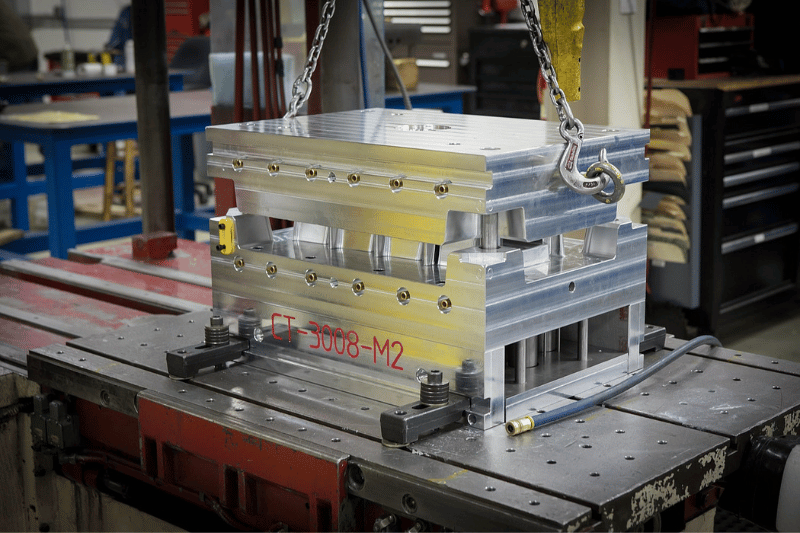

Materials used injection mould

The various materials used to create injection moulds, also known as injection moulding tools, typically provide strength, heat resistance, and a stable dimensional structure. The type of product being designed, the volume of production, and economic concerns are only a few examples of the variables that influence the material choice.

P-20 steel

Due to its favourable mix of durability, corrosion resistance, and machinability, P-20 steel is preferred for injection moulds. It compromises cost and performance and is frequently utilised for small to high-volume production.

Beryllium copper

This substance has outstanding mechanical qualities, strong thermal conductivity, and good corrosion resistance. Beryllium copper moulds are frequently utilised for applications needing high electrical or thermal conductivity, such as some electronic components.

Aluminium

Since aluminium is less expensive and can be machined more quickly than steel, it is frequently used for prototypes and low-volume production. Aluminium moulds may nevertheless manufacture a sizable number of pieces before needing replacement, despite not being as sturdy as steel moulds.

Steel

Due to its outstanding toughness, resilience to wear, and heat conductivity, steel is the most often used material for injection moulds.

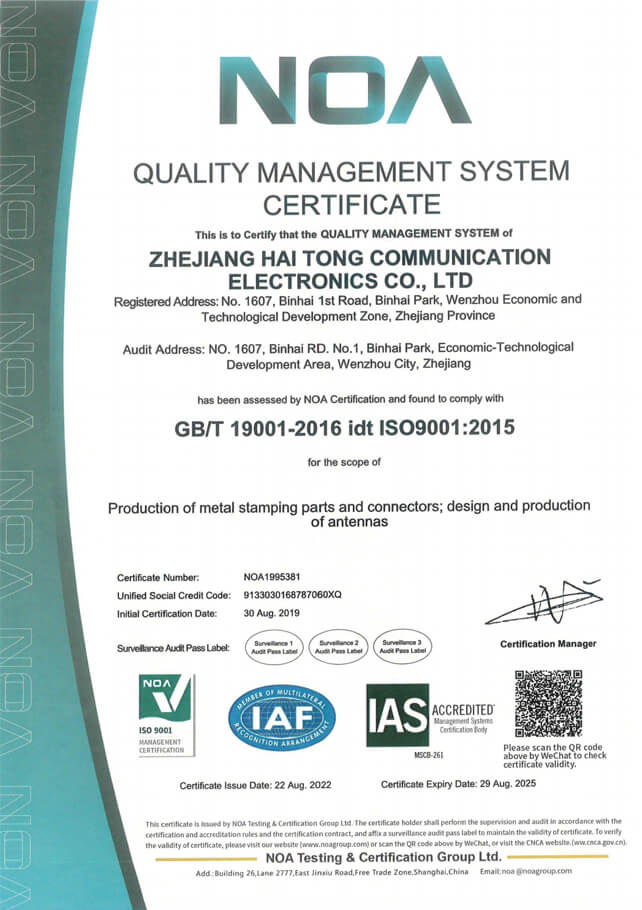

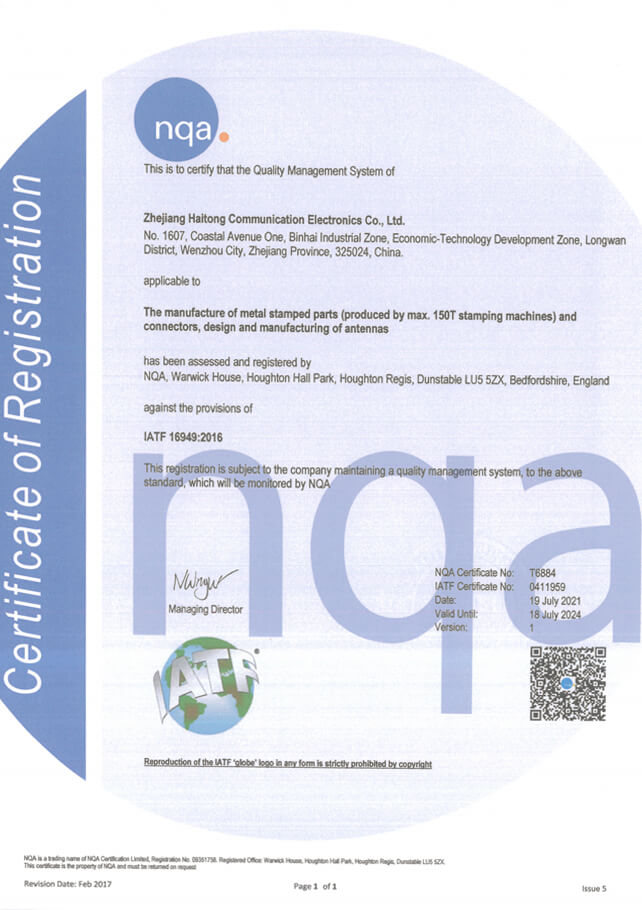

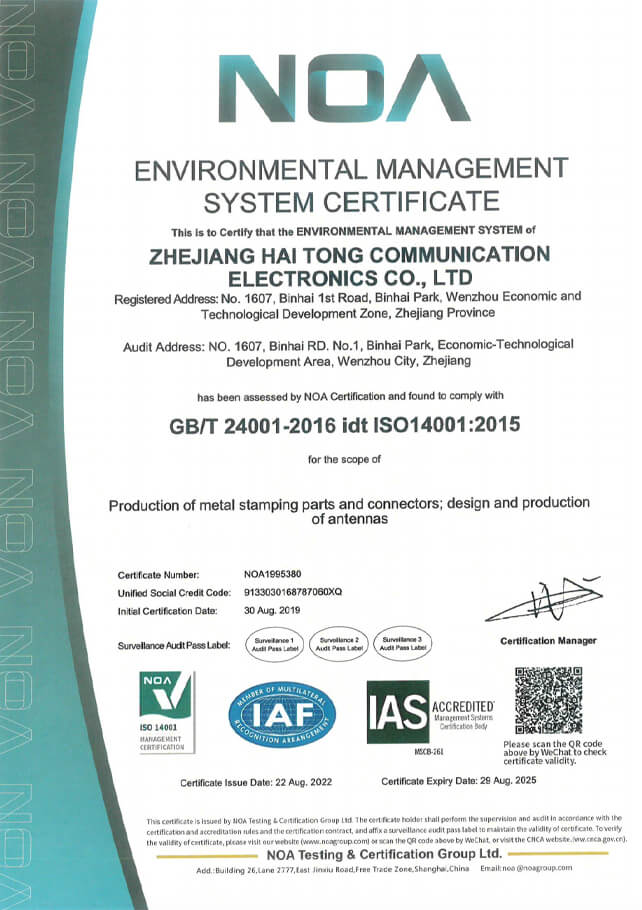

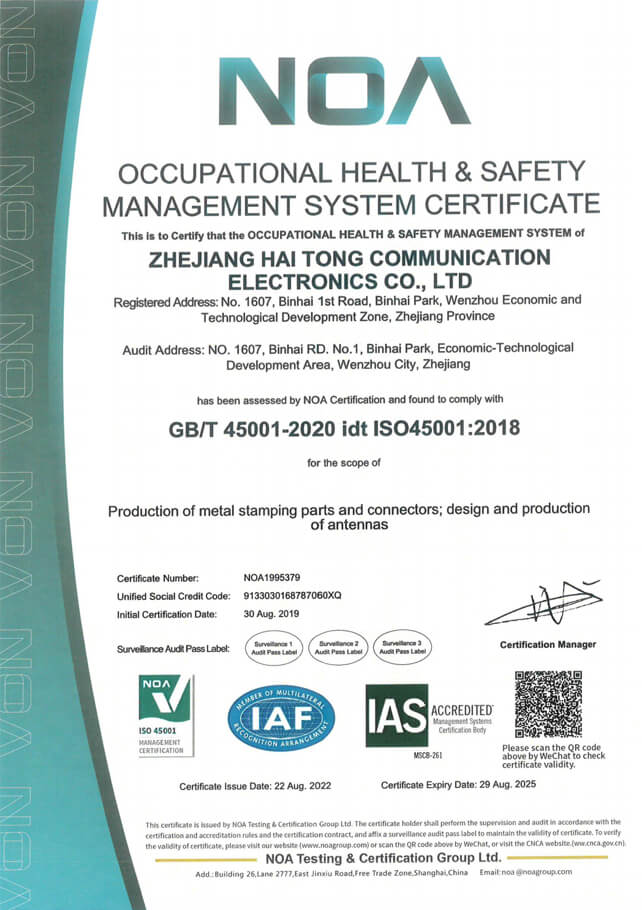

Our certification

process

Application industry and case

WHAT WE DO

Automotive Industry

Laboratory Equipment

Electronics and Electrical Industry

Buildings and Constructions

Aerospace industry

Choose Nhait for top-quality injection mould manufacturing solutions that meet your exact specifications, delivering precision, efficiency, and reliability.

Why Choose Us

Because we combine knowledge with modern technology to produce high-quality moulds that satisfy your requirements, pick us as your injection mould manufacturer. Our committed team guarantees effective production and prompt delivery, giving you a reliable supplier for all your injection moulding requirements.

Years of Industry Experience

We have developed our competence in injection moulding over the years, ensuring high-quality goods and effective manufacturing procedures.

Modern Technology

We can take advantage of the most recent developments in injection moulding technology thanks to our cutting-edge facilities and equipment, resulting in precise and defect-free production.

Capabilities for Customization

We are experts at producing customised injection moulds that are made to your exact specifications and that give flexibility in design, functionality to satisfy your requirements.

Cost-Effectiveness

To provide value for your investment, we prioritise cost-efficiency without sacrificing quality. To do this, we offer competitive pricing alternatives, reduce material waste.

We understand the significance of finding the ideal solution for your application and are more than willing to provide you with all the necessary information you need. Reach out to us today for a comprehensive understanding of our stamping services and how they can meet your specific requirements.

Sales Support

At Nhait, we place utmost importance on our customers' needs and requests. Our dedicated team is here to assist you every step of the way, ensuring a seamless and satisfactory experience.

Sample Test

Upon receiving a customer's purchase, we are committed to providing samples within a time frame of 20-30 days. Our goal is to ensure prompt delivery and customer satisfaction.

Custom Solution

We specialize in providing custom solutions for all your stamping service needs. Our advanced machinery and utilization of the latest production methodologies allow us to deliver exceptional results.