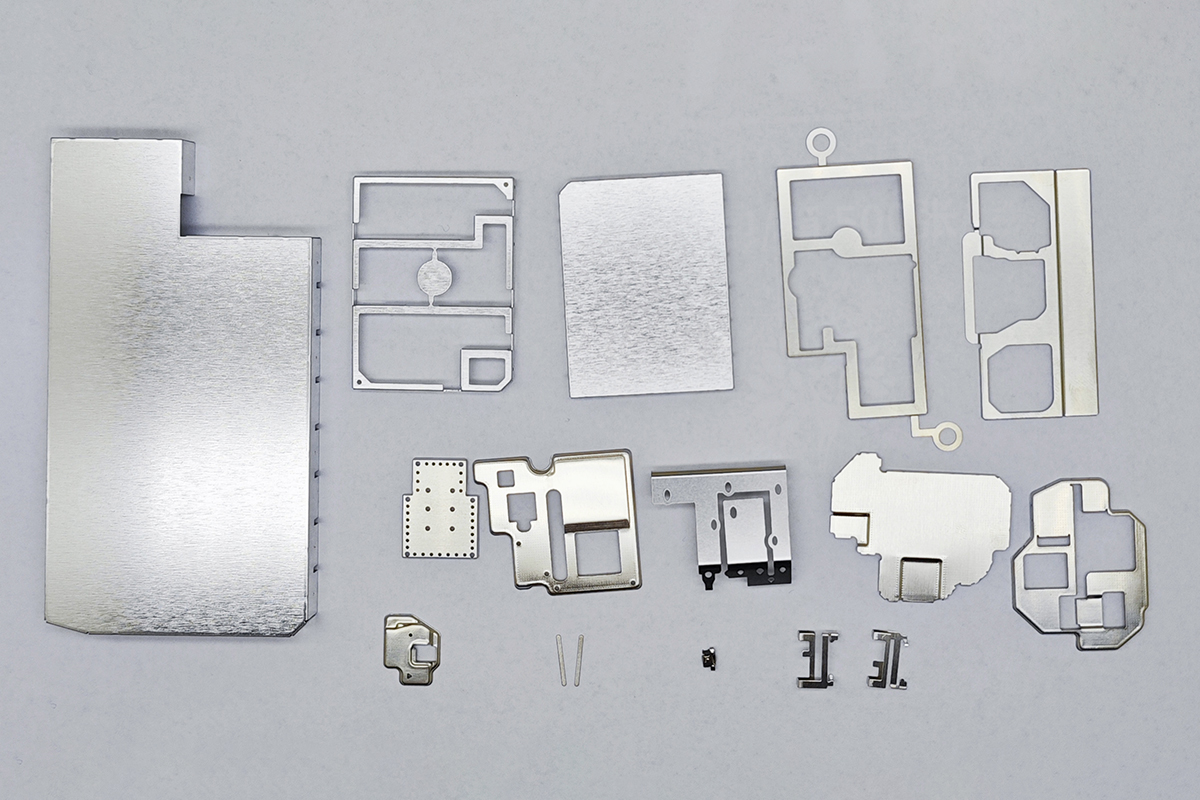

PCB Shielding

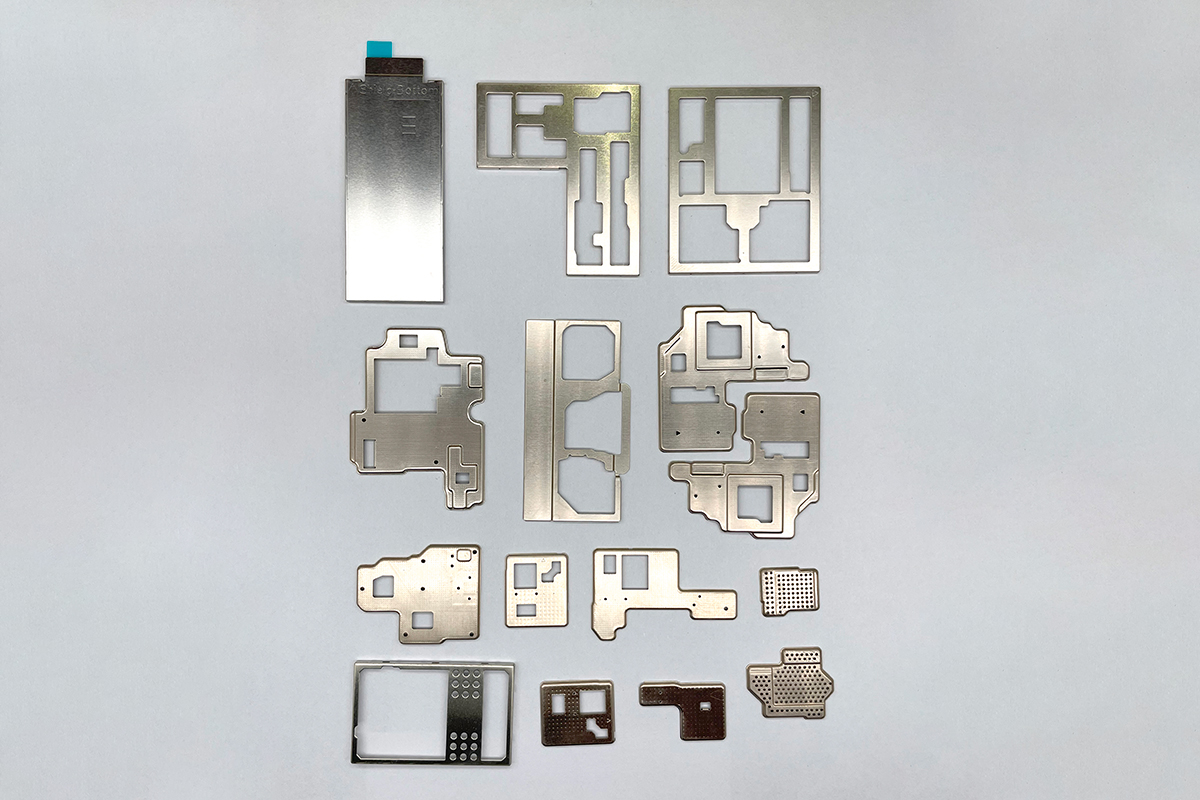

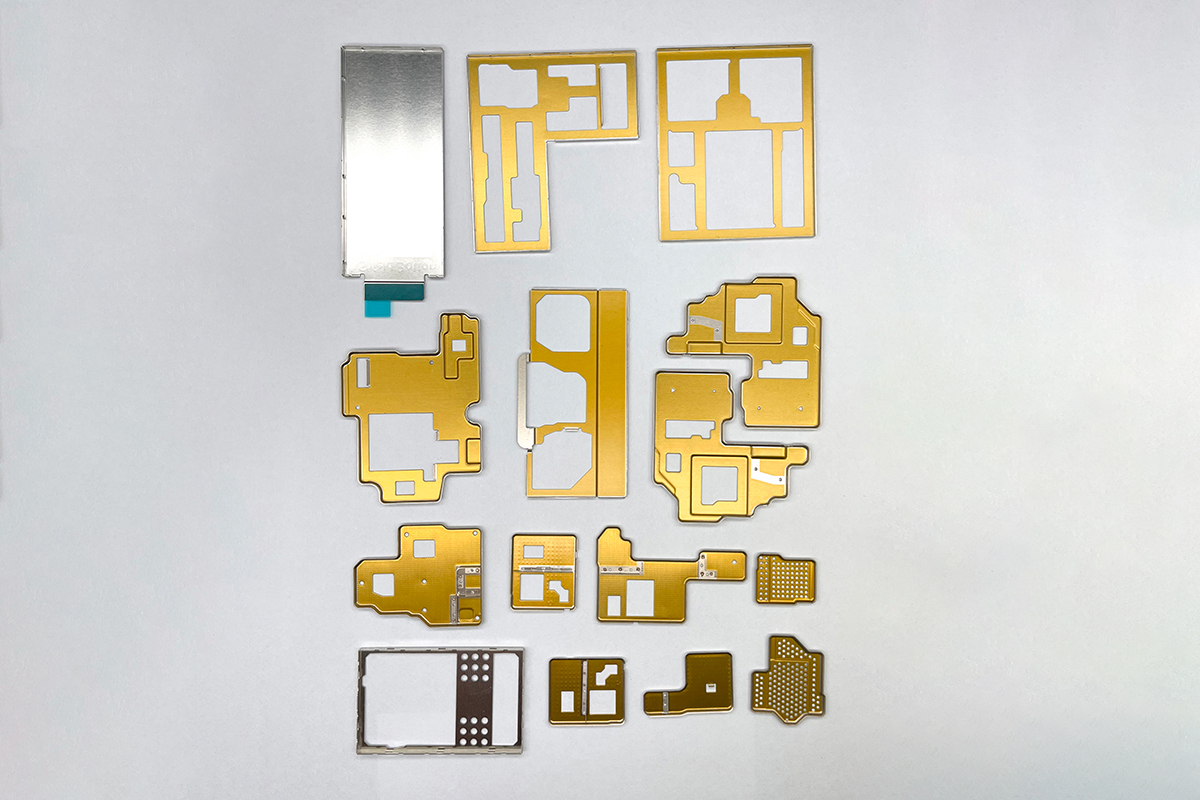

Printed circuit boards (PCBs) need to be shielded from radio frequency interference (RFI) and electromagnetic interference (EMI) in electrical design.

PCBs may retain signal integrity and stop undesirable noise or disturbance from impairing their performance by utilising shielding components and methods, such as metallic coatings or metal casings.

PCB Shielding Technology

Electronic equipment depends on PCB (Printed Circuit Board) shielding to ensure dependable and effective functioning by reducing electromagnetic interference (EMI) and radio frequency interference (RFI).

Shielding is often accomplished by strategically positioning conductive materials, like metal foils or finishes, all around the PCB circuits.

This shielding protects sensitive circuitry from interference from outside electromagnetic radiation, and PCB emissions are also contained. Signal integrity is maintained, noise is reduced, and electronic systems’ overall electromagnetic compatibility (EMC) is improved with effective PCB shielding.

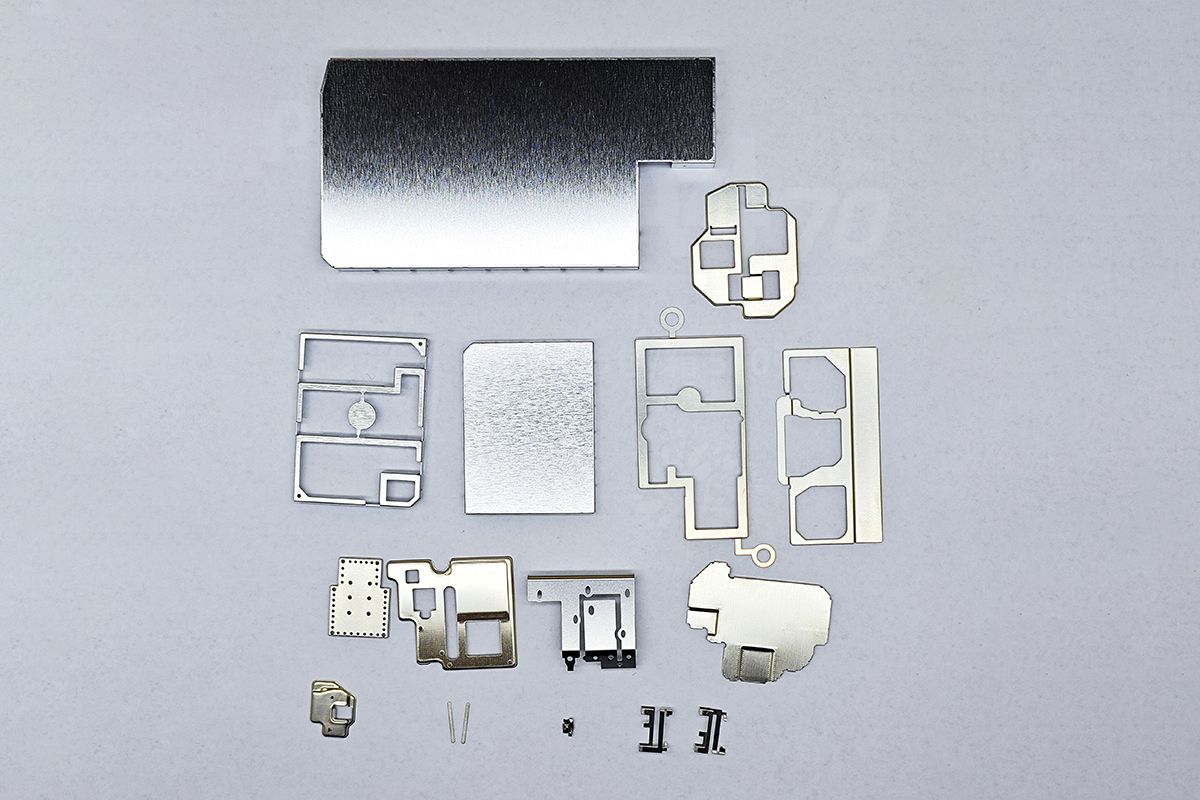

Choice of Shield Type

WHAT WE DO

One-piece RF shield

Application

Two-piece shield

Application

Drawn RF shield

Application

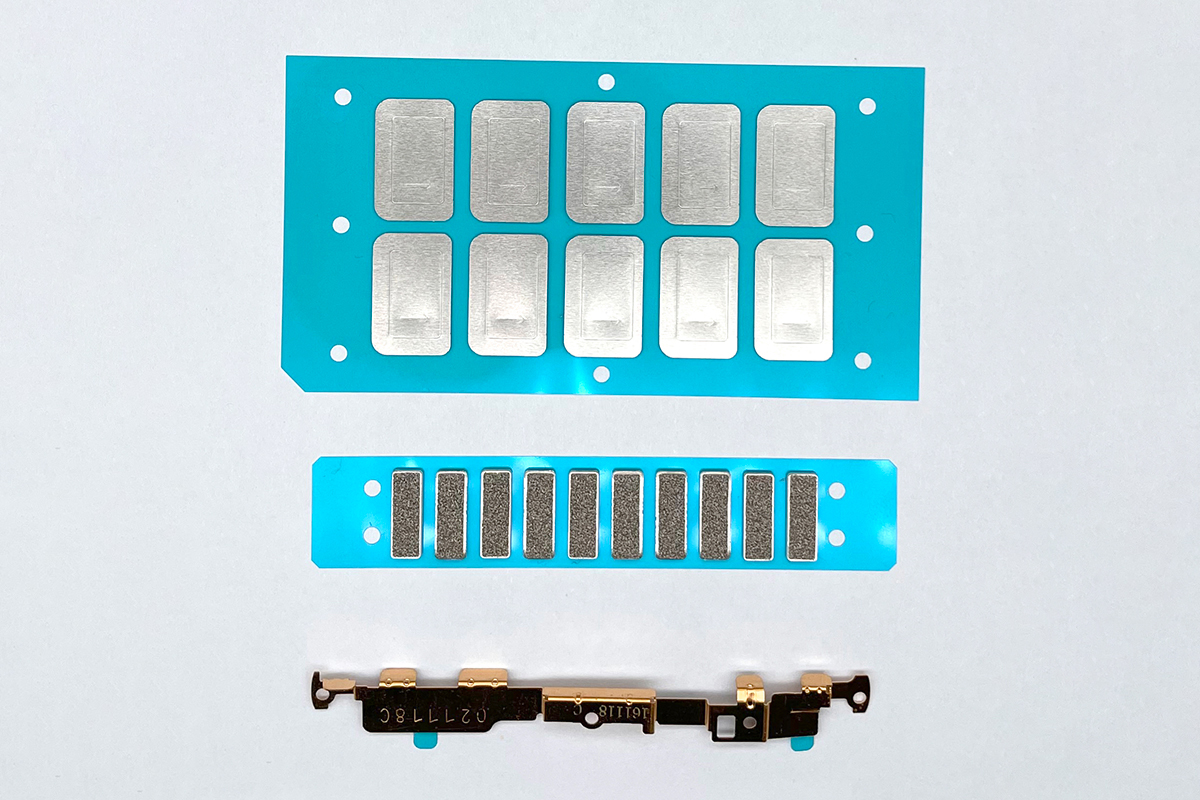

Surface-mounted shield(SMS)

Application

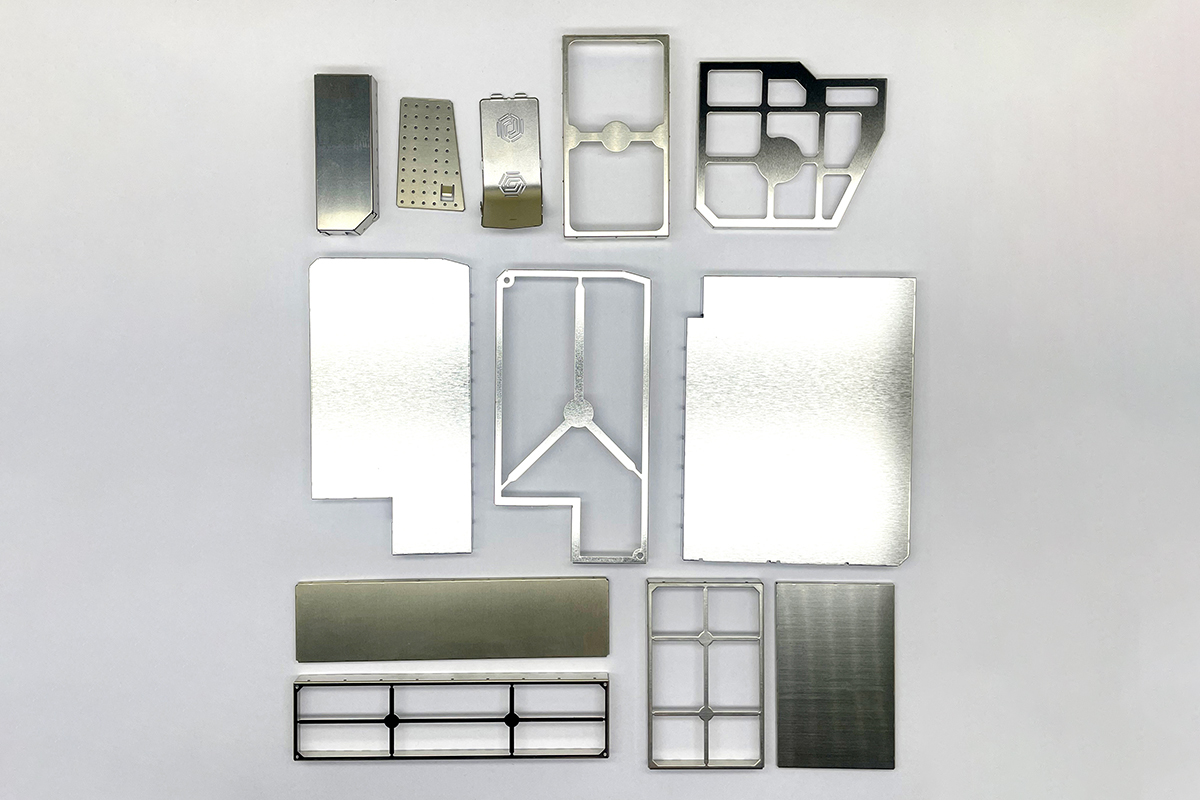

MultivCAV shields

Application

SMT shield clips

Application

24/7 Towing Service

24/7 Assistance

Custom PCB Shielding Cans Solution

WHO WE ARE

Processes in the Design and Production Stage for Shield

01

Type of board-level shielding

Metallic paints, aluminium walls, and conductive seals are a few examples of several kinds of board-level shielding methods. These shielding techniques protect against signal loss and interruption and guarantee the dependable performance of electronic parts.

Material for board-level shielding

Board-level shielding material selection is based on the needs of the application. Conductive metals like copper, aluminium, and stainless steel are often utilised materials because they offer great electrical insulation and shielding effectiveness. The right material should be chosen

02

Packaging of board-level shielding

Board-level shielding must be packaged properly to maintain its integrity and effectiveness. The shielded elements or circuits are often enclosed in a housing or protective enclosure as part of the packaging process. In order to avoid interference or emissions, the packaging design should take electromagnetic compatibility (EMC) requirements into account as well as being accessible for repairs and maintenance and temperature control.

03

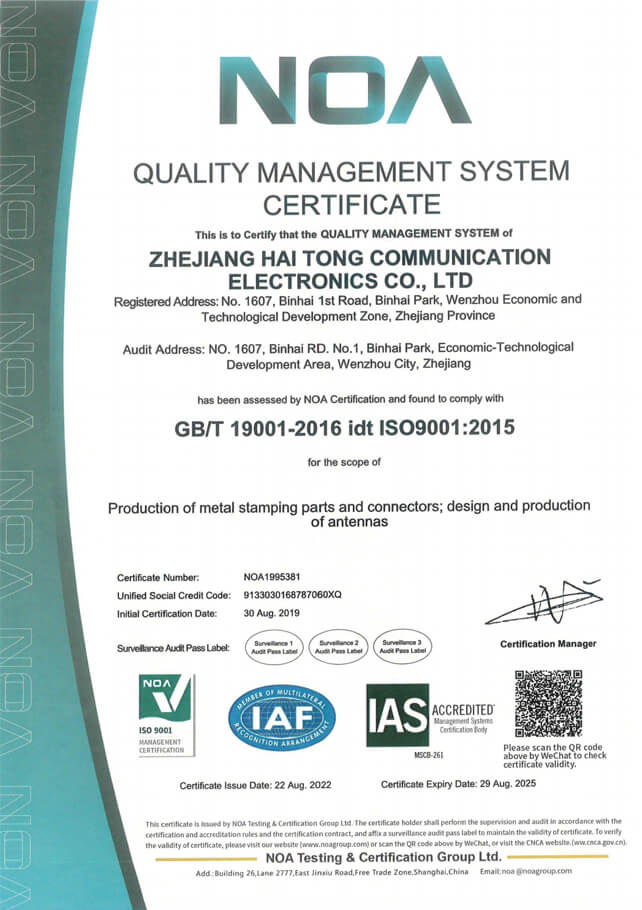

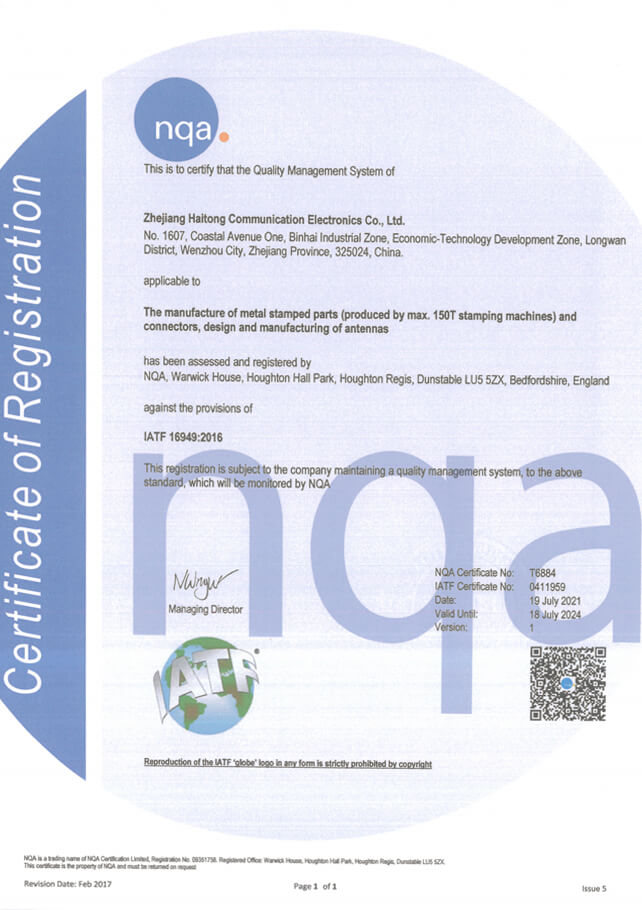

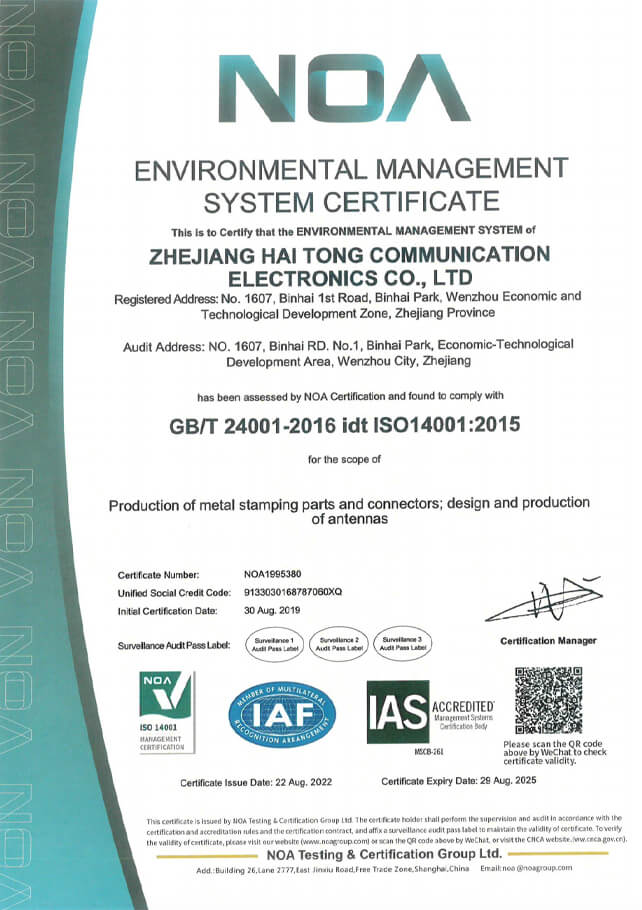

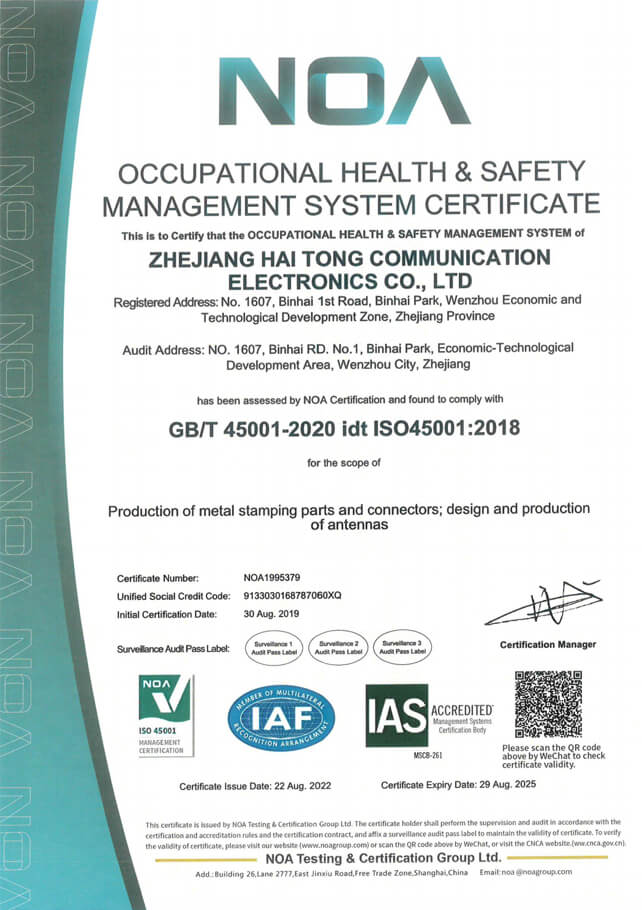

Our certification

As a leading manufacturer of PCB emi shields, we take great pride in our certification, which guarantees the dependability and effectiveness of our products.

Our certification proves our commitment to quality while assuring customers that our rf shield cans solutions comply with the most critical industry standards. The NOA’s criteria have been satisfied.

Why Choose Us

Tailored Solutions

We specialise in offering PCB shielding solutions that are specifically tailored to meet your needs, ensuring an exact fit and top performance.

Innovative Manufacturing Procedures

We produce effective and affordable shielding solutions without sacrificing quality by utilising innovative manufacturing techniques.

High-quality Materials are Guaranteed

We craft our shielding solutions using premium materials to ensure their sturdiness, dependability, and overtime PCB protection.

Experienced Technical Service

To help you get the best shielding outcomes, our team of knowledgeable experts is committed to providing thorough technical support. They will work with you during the development and execution processes.

Better Shielding Operation

Our PCB shields are painstakingly designed and made to provide superior PCB EMI shielding performance, successfully decreasing electromagnetic interference (EMI), and ensuring the best performance of electrical equipment.

Customization choices

We provide a variety of customization choices because we recognise that each project has specific requirements. We may customise our shielding products to match the unique requirements of our clients, taking into account size, form, materials, and coatings.

Rapid Turnaround

We take pleasure in our ability to provide prompt and effective solutions. We try to deliver short turnaround times without sacrificing the high