Stamping Tool Manufacturer

Stamping Tool Procedures

WHAT WE DO

Step 1: Creation of Designs and Concepts

The stamping tool's function, dimensions, and general design are decided upon in this initial step. Developing a clear vision for the device requires brainstorming, sketching, and getting feedback from stakeholders.

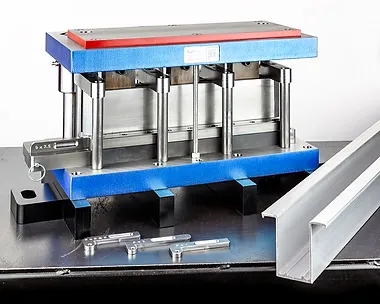

Step 2: Selection of Materials and Testing

After the design has been decided upon, the best materials are selected by criteria including cost-effectiveness, durability, and suitability for the intended application. A workable model is then developed through prototyping, enabling verification and testing of the functionality of the design.

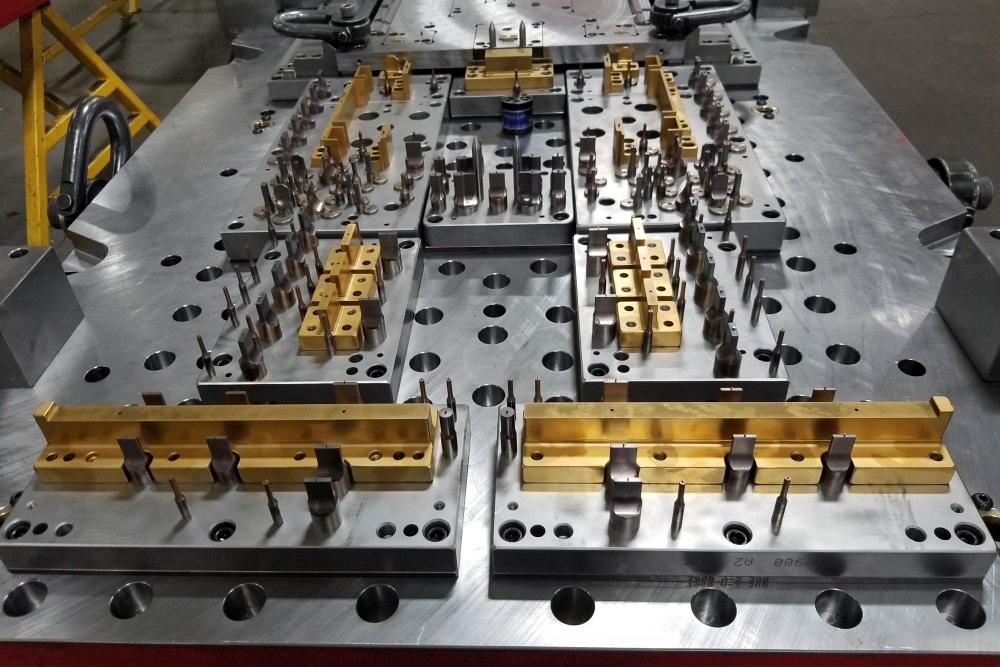

Step 3: Tool Manufacturing

The stamping tool is constructed using the prototype as a guide. This entails precisely shaping, assembling, and machining the chosen materials to ensure that the device satisfies the standards and can endure the pressures applied during stamping.

4. Testing and Developing

The finished stamping tool undergoes a series of rigorous tests to gauge its effectiveness. Any problems or shortcomings are located and fixed, which leads to improvements in the blueprint or manufacturing procedure.

24/7 Towing Service

24/7 Assistance

Stamping Tooling Solution

WHO WE ARE

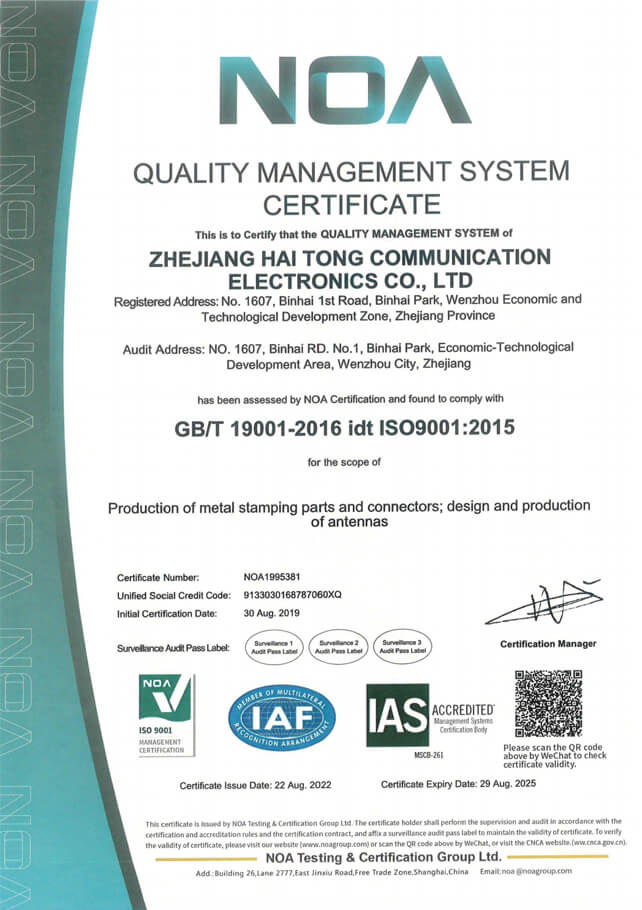

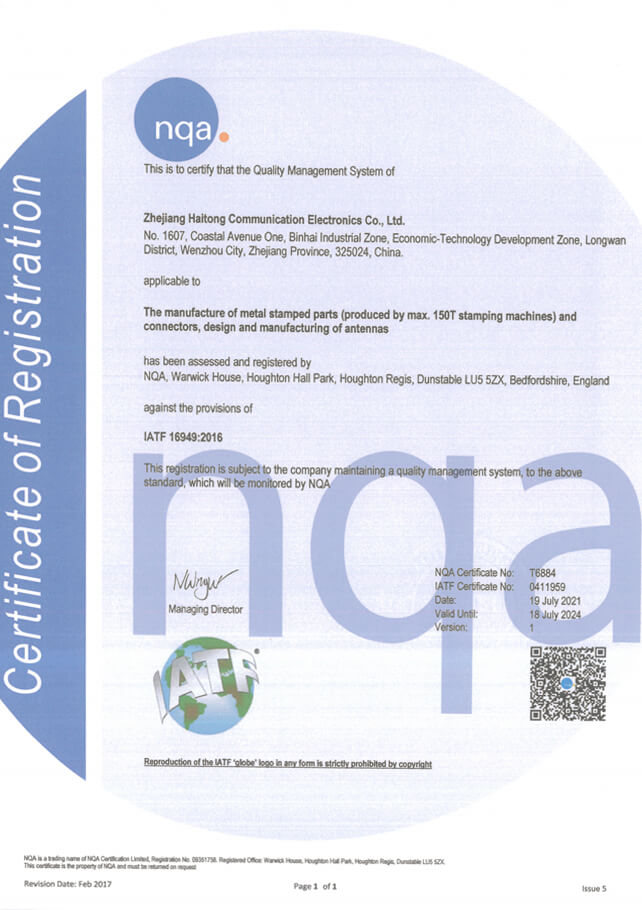

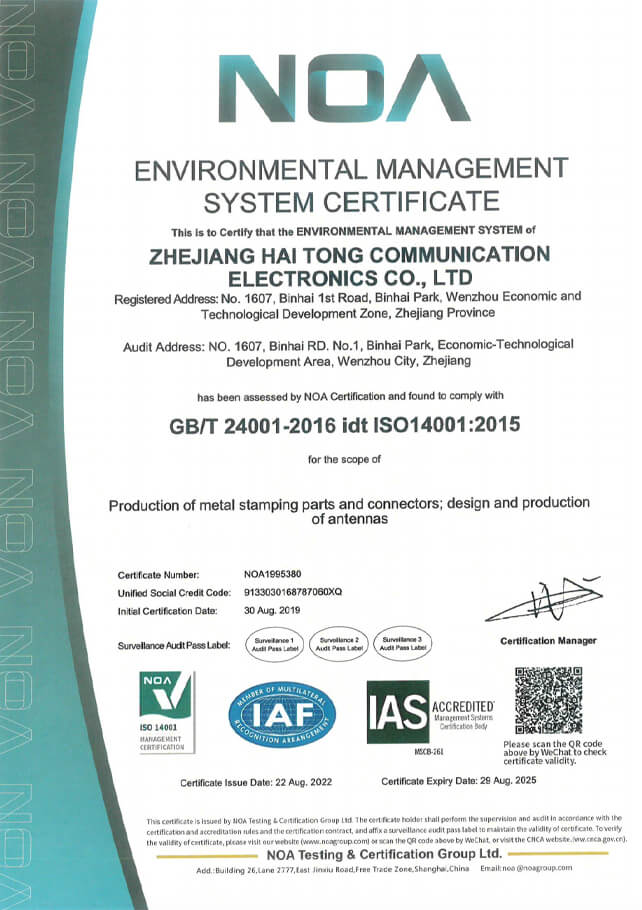

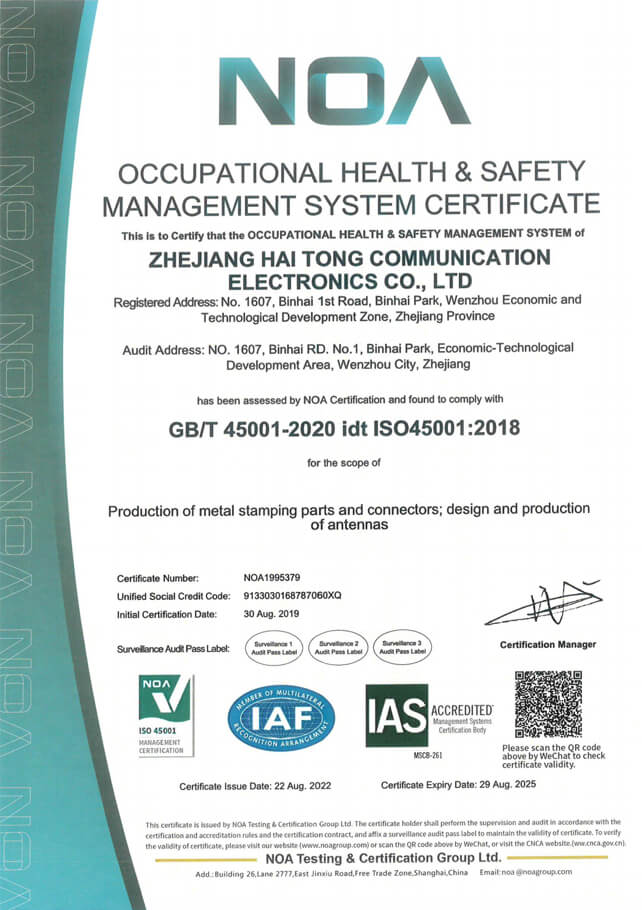

Our certification

process

Stamping Tool Materials

Steel

Due to its exceptional endurance and strength, steel is a frequently utilised material for stamping tools. Assuring long-lasting performance, it is capable of withstanding the high forces and repeated impacts that occur during stamping processes.

Aluminium

Aluminium is an easy-to-carry reasonably priced material that is used in stamping equipment when weight reduction is crucial. It is suitable for stamping operations because it has good heat conductivity and is simple to process.

Carbide

The most common type of carbide is tungsten carbide, which is prized for both its extreme hardness and resilience to wear. When employing rough materials, stamping tools are frequently used to extend their service life while retaining sharp cutting edges.

Tool Steel

Known for its exceptional hardness, toughness, and wear resistance, tool steel is a flexible material option for stamping tools. It is a popular choice in many industries because it can be tailored with various alloy compositions to satisfy specific stamping needs.

Application industry and case

WHAT WE DO

Medical Devices

Construction Sector

Energy Sector

Furniture Manufacturing

Electronics Manufacturing

Automobile Industry.

Why Choose Us

Green Manufacturing Methods

To reduce our ecological imprint, we utilise sustainable manufacturing methods as part of our adherence to environmental responsibility.

Low Pricing

You may maximise your budget without sacrificing quality thanks to the outstanding value offered by our affordable options.

Customer satisfaction

Customer satisfaction is important to us, and we work hard to go above and beyond to meet your expectations with our top-notch goods and services.

Speedy Dispatch

Your stamping tools will always be delivered on schedule because we place a high priority on punctual delivery.

Cutting-Edge technological advances

We make stamping tools with exceptional performance thanks to the use of sophisticated machinery and creative manufacturing processes.

Flexible customization

Flexible customization possibilities are available from us, enabling you to create stamping tools that are designed for your unique needs.