Die-casting Mould Manufacturer

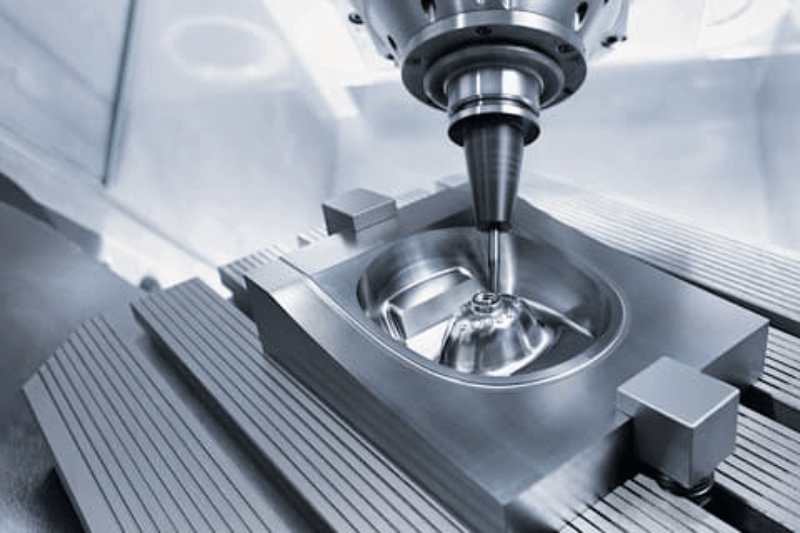

Nhait is a prominent manufacturer of die-casting moulds renowned for our skill in creating moulds of the highest calibre. Nhait produces custom moulds to its client’s specifications, emphasising efficiency and precision, resulting in seamless die-casting operations.

Die-casting Mould Capabilities

WHAT WE DO

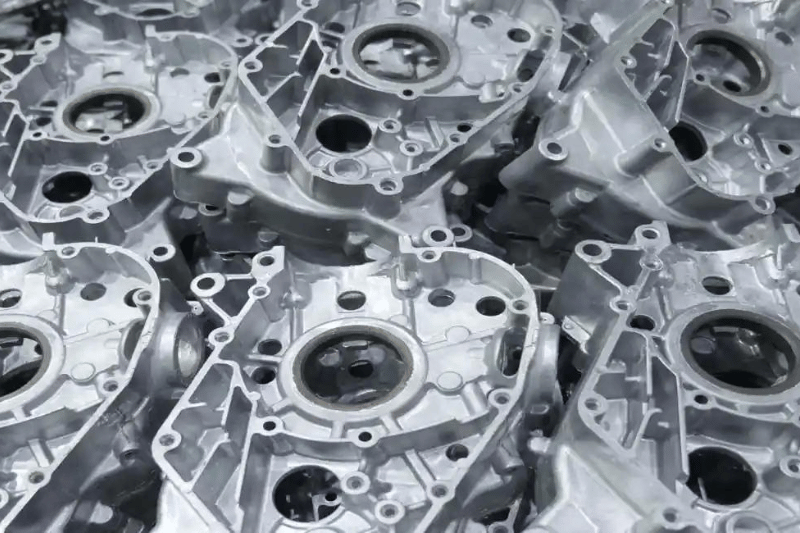

Unmarried Cavity Mould

A die-casting mould with only one cavity that can produce one part every casting cycle, making it ideal for designing prototypes or large workpiece products.

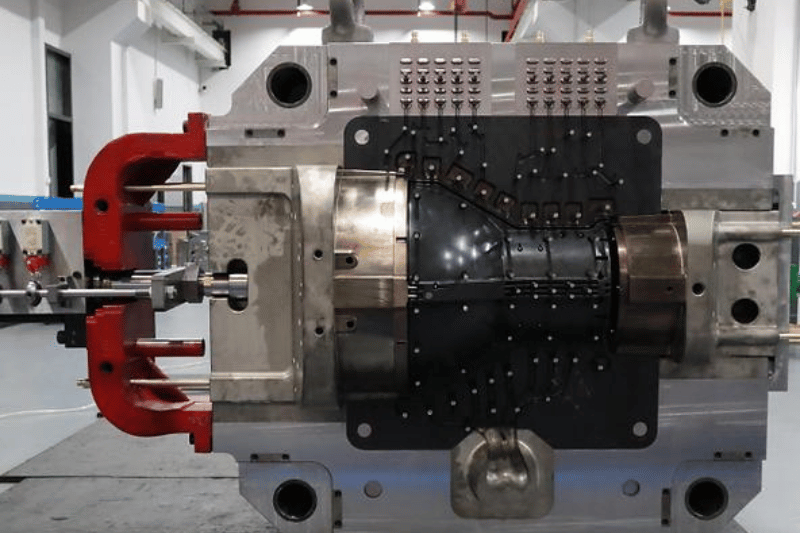

Numerous Cavity Mould

his kind of die-casting mould has numerous cavities that enable the concurrent manufacture of multiple pieces in each casting cycle, increasing productivity and cost-effectiveness for big workpiece products.

Combination Die Mould

A combination die mould combines the advantages of both single and multiple cavity moulds, enabling the manufacturing of several parts within the same casting cycle while keeping some degree of versatility and individualisation.

24/7 Towing Service

24/7 Assistance

Custom Die-casting Mould Solution

WHO WE ARE

Introducing our innovative custom die-casting mould solution, where efficacy and accuracy meet. We deliver customised moulds that optimise production, improve product quality, and shorten time-to-market for various sectors thanks to our in-depth knowledge of die-casting techniques and modern technology.

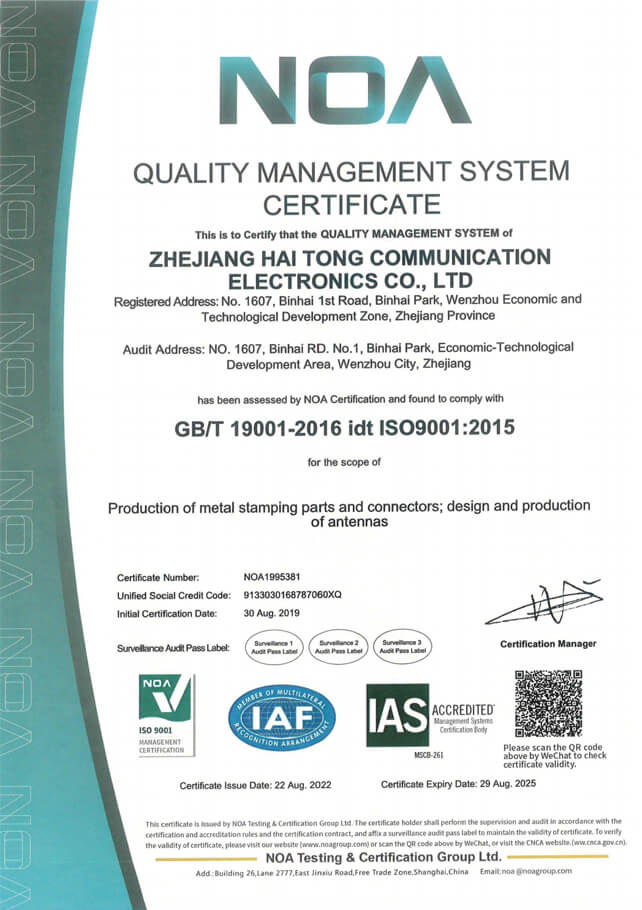

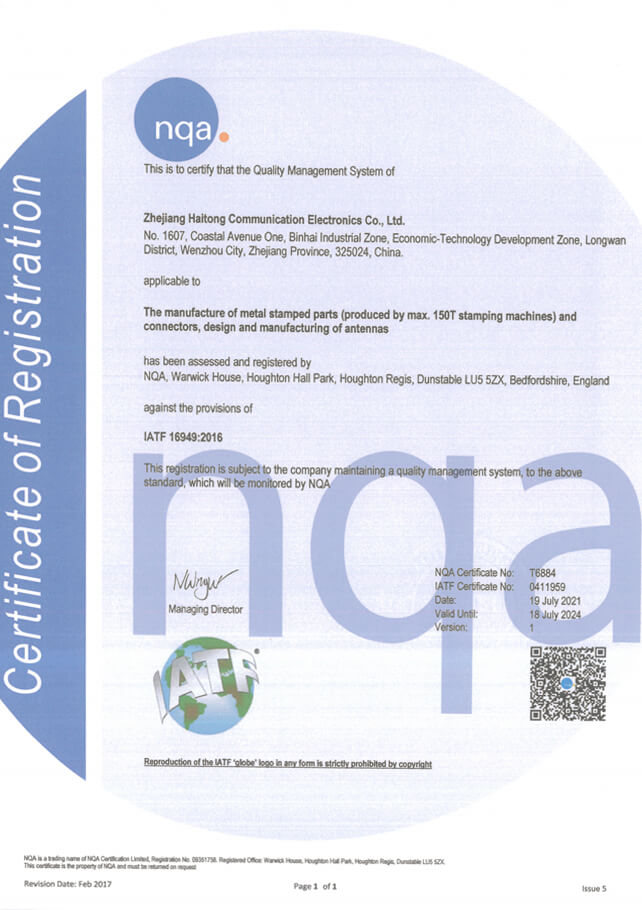

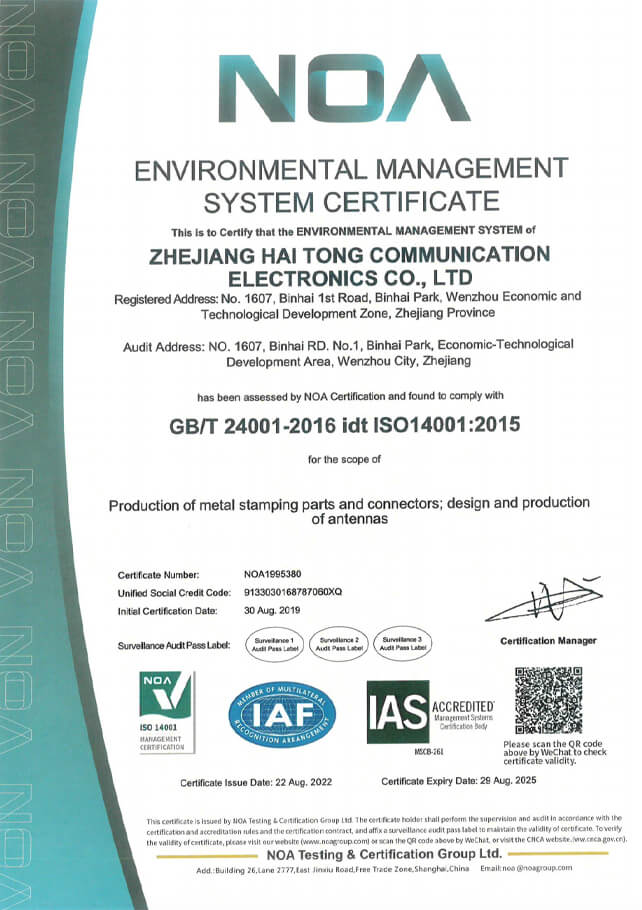

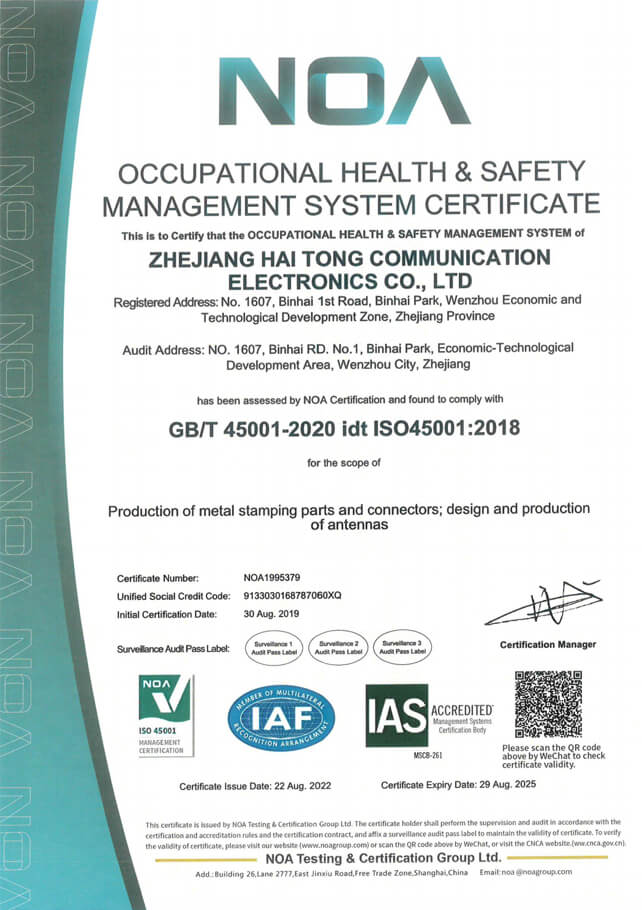

Our certification

process

Application industry and case

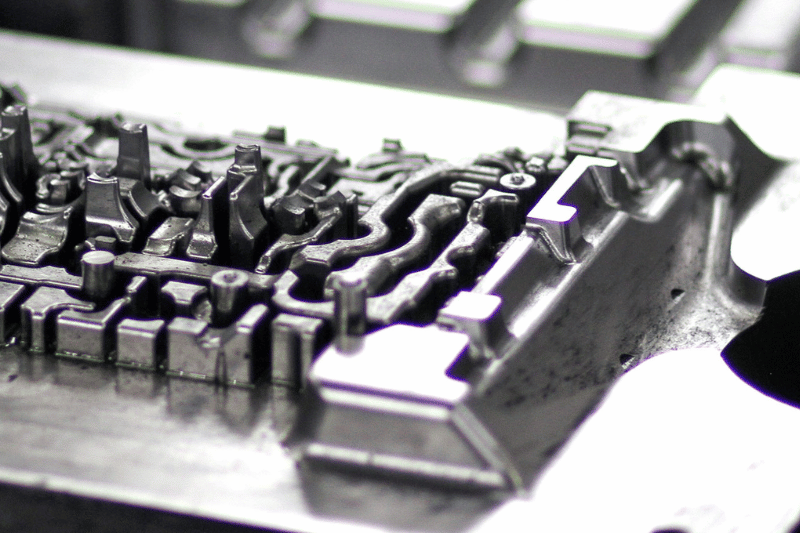

High-quality materials like steel or iron are frequently used to create die-casting moulds. These materials are chosen for their longevity, temperature resistance, and capacity to keep intricate geometries, which enables the manufacture of high-quality and exact castings.

WHAT WE DO

Zinc Alloy

Magnesium Alloy

Aluminium Alloy

Titanium Alloy

Take your production to the next level by learning more about the accuracy and superiority of Nhait die-casting moulds today!

Why choose us?

Nhait stands out as a dependable and trustworthy option for die-casting mould production. With our extensive industry knowledge and dedication to producing high-quality moulds, we offer specialised solutions to match your unique requirements, assuring accuracy, robustness, and economic efficiency for your die-casting procedures.

Innovative Thinking

We promote a culture of continual development and look for new ways to increase the effectiveness and performance of our die-casting moulds.

Extensive Support

Our devoted customer service staff is always on hand to solve any questions or problems you may have, from the initial consultation through post-sales help.

Industry Name

As a result of our solid standing in the manufacturing of die-casting moulds, we have earned a reputation for dependability and client satisfaction.

We are a die-casting mould manufacturer, and we specialise in producing excellent moulds for various industries. We are dedicated to delivering precision-engineered solutions that satisfy the unique requirements of our clients using our knowledge and cutting-edge facilities, assuring effective and dependable die-casting production processes.

Material Flexibility

You may work with a variety of materials and get the results you want because our die-casting moulds are made to accept different materials.

Prompt Shipping

We recognise the value of timely delivery, and our well-oiled production and logistical processes guarantee that your die-casting moulds will be delivered on schedule.

Experience and Knowledge

Our talented staff has years of industry experience, and they provide a wealth of knowledge and expertise to produce high-performance die-casting moulds.