EMI Shielding Solutions

Shielding from electromagnetic interference, or EMI is crucial in today’s technologically advanced environment. The need to reduce electromagnetic interference is becoming increasingly critical as electronic gadgets get smaller and more potent.

Sensitive components are shielded from ambient electromagnetic waves using efficient EMI shielding techniques and materials, resulting in maximum functionality and dependability.

EMI Shielding Technology

Modern electronic systems and equipment must include EMI (Electromagnetic Interference) shielding. A suitable EMI shielding design guide is now essential since wireless technology is developing and electromagnetic pollution is increasing.

To reduce electromagnetic emissions and vulnerability, which can interfere with electronic circuits, materials and structures must be strategically used. By restricting electromagnetic waves’ unwelcome transfer and reception, EMI shielding companies provide the highest levels of efficiency, reliability, and conformity to electromagnetic compatibility regulations.

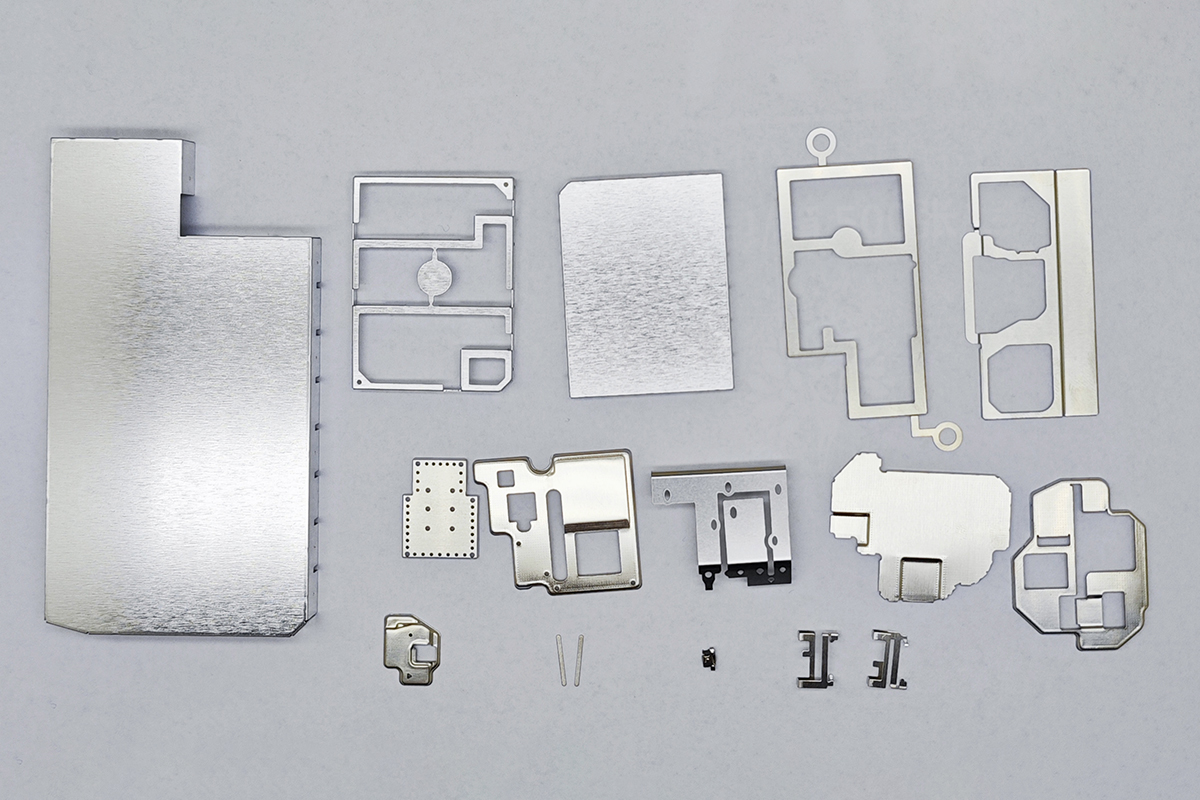

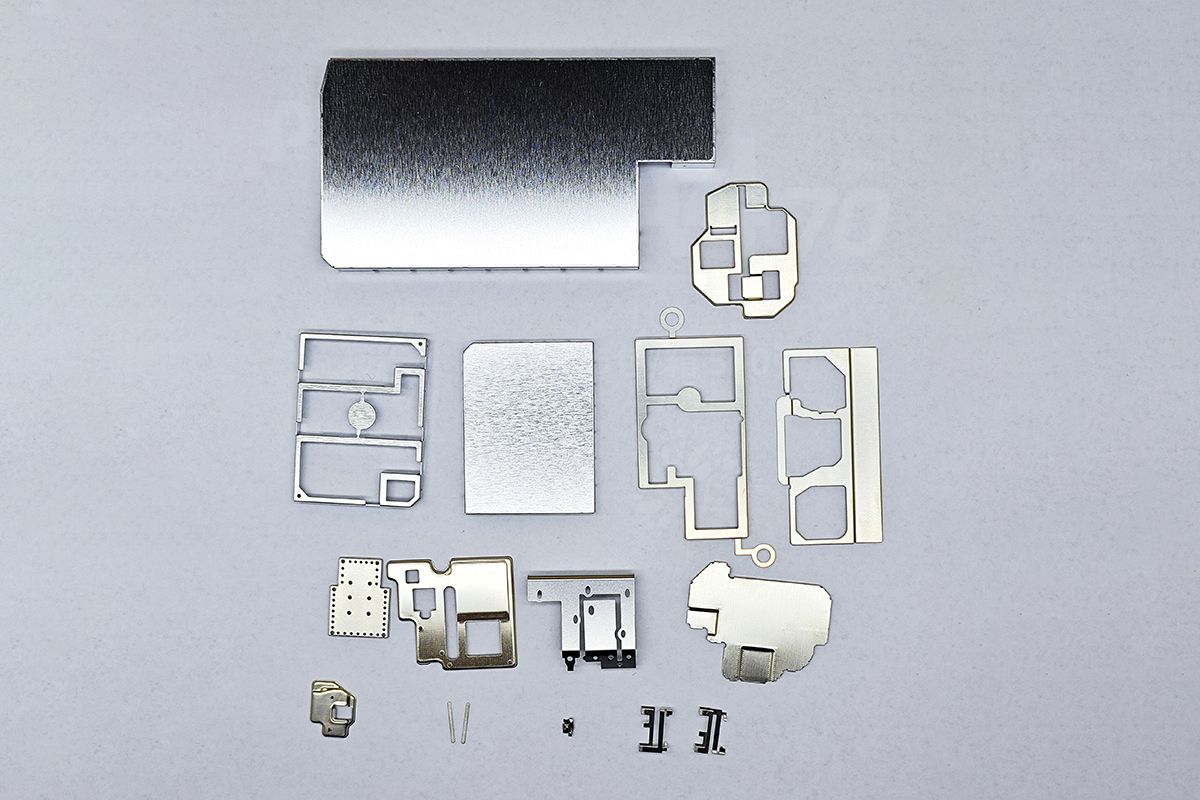

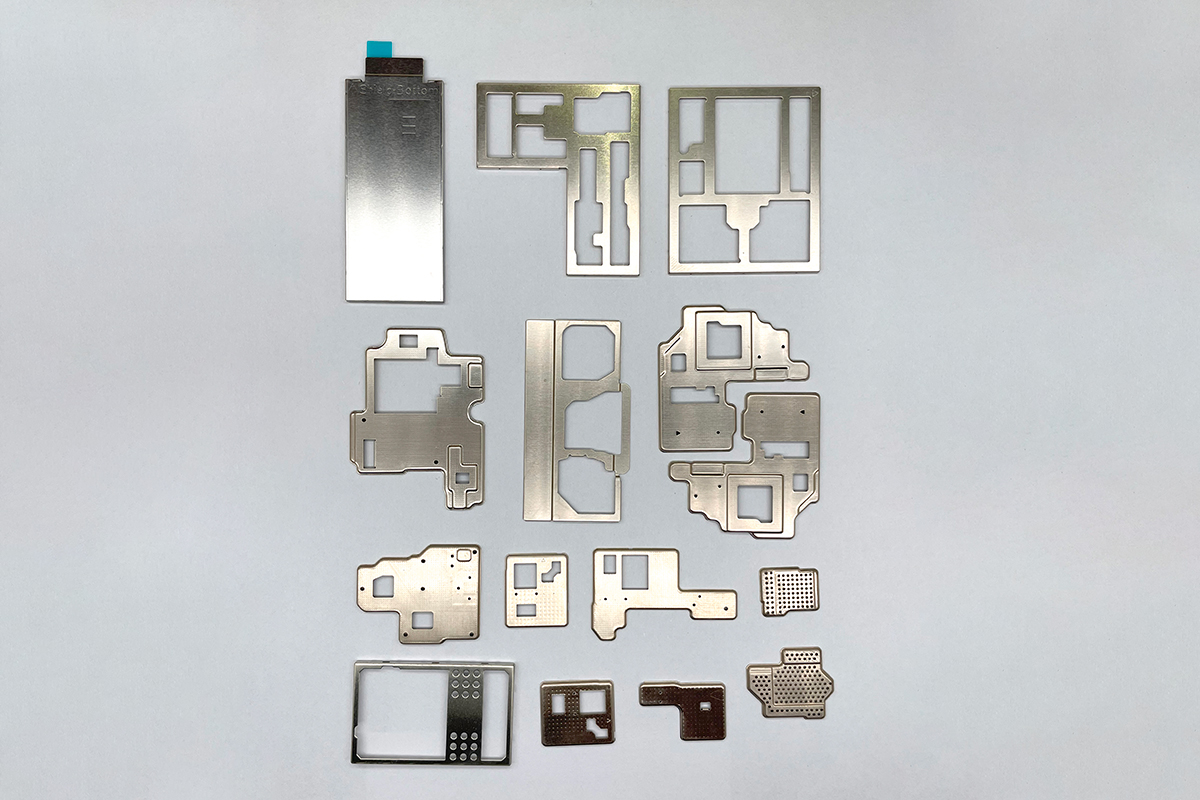

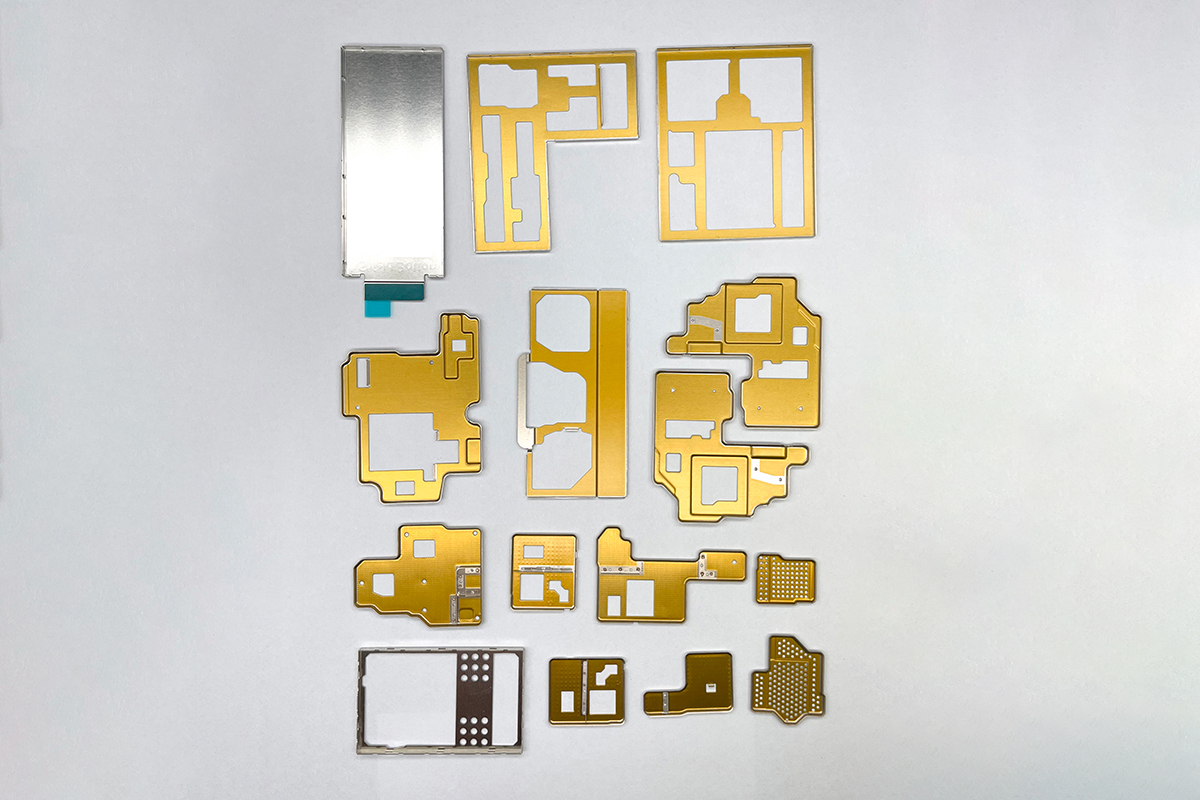

Choice of Shield Type

WHAT WE DO

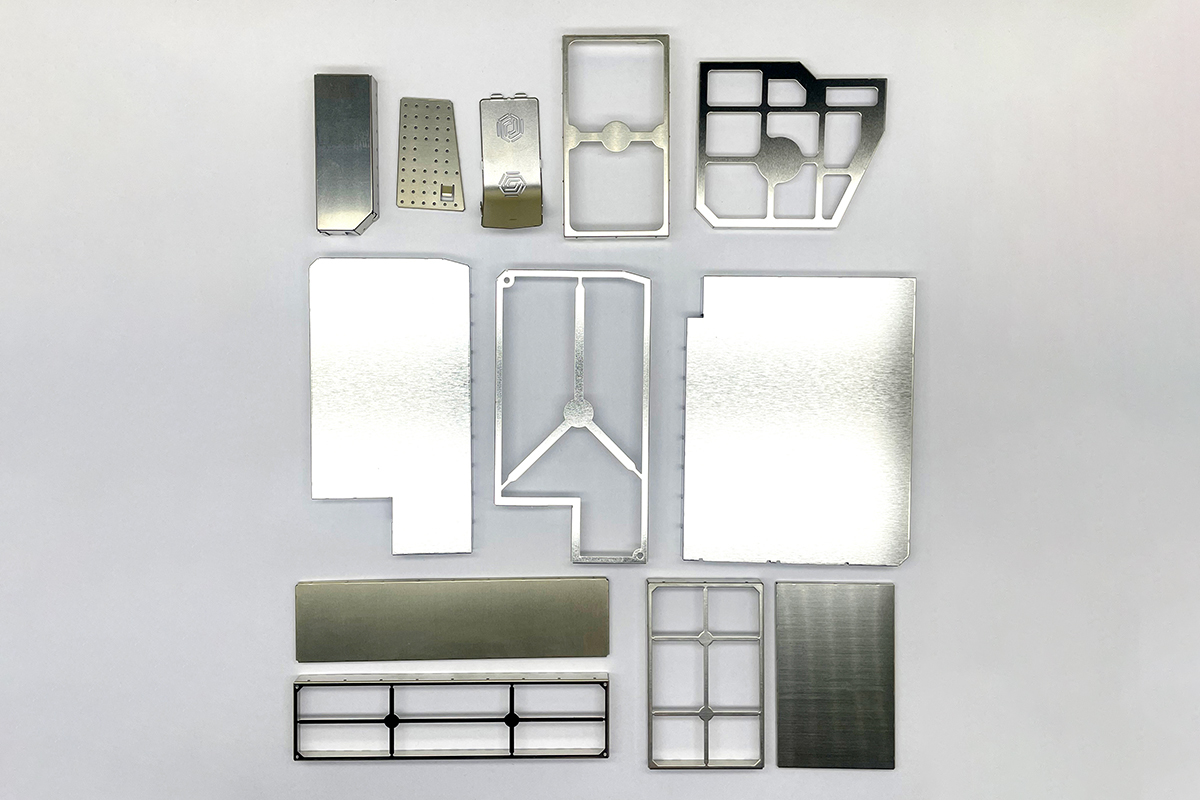

One-piece RF shield

Application

Two-piece shield

Application

Drawn RF shield

Application

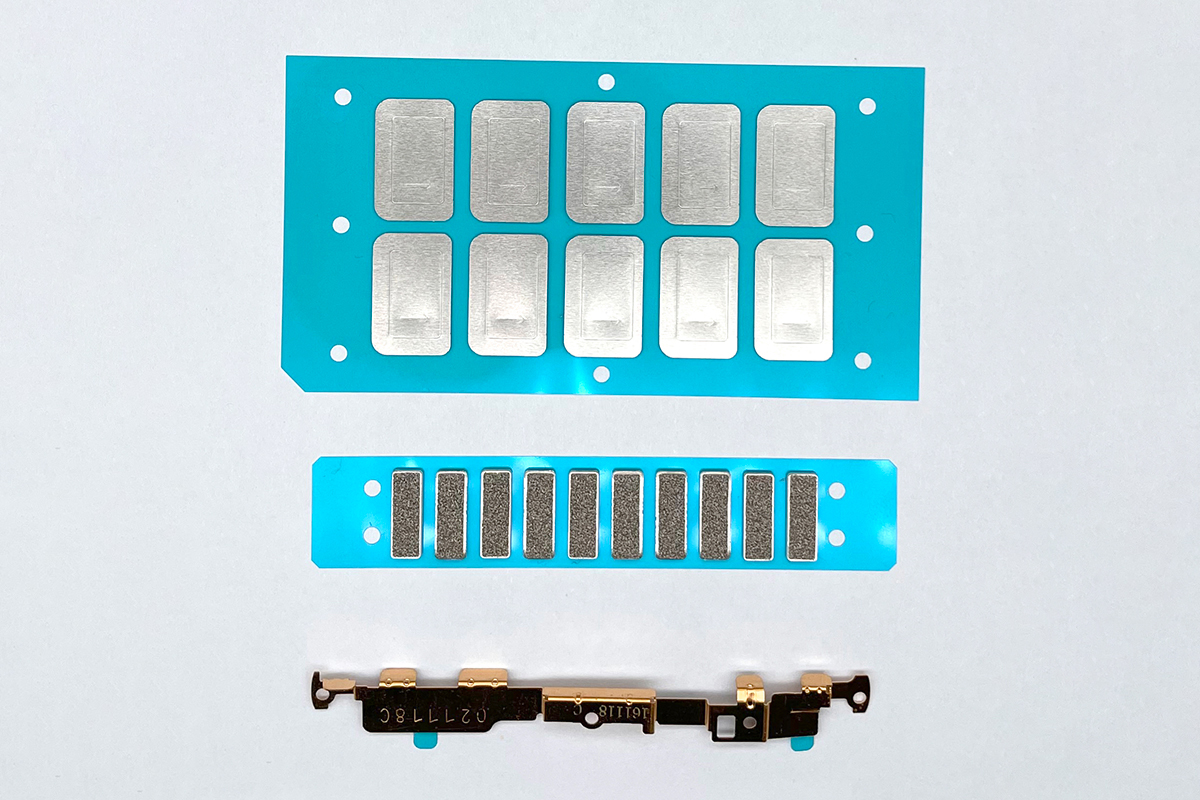

Surface-mounted shield(SMS)

Application

MultivCAV shields

Application

SMT shield clips

Application

24/7 Towing Service

24/7 Assistance

Custom EMI Shielding Cans Solution

WHO WE ARE

Processes in the Design and Production Stage for Shield

01

Board-level shielding design

There are many different types of board-level shielding techniques, including metallic coatings, metal walls, and conductive sealing. These shielding methods ensure the dependable operation of electronic components by guarding against signal corruption and disruption.

Selection of suitable materials

The choice of the best material for board-level shielding during the design and production stages of EMI shielding is the second phase. Here, specifications like conductivity, strength, and conformity with the proposed use are taken into account.

02

Board-level shielding packaging

After selecting the board-level shielding material, the next step entails carefully packing and attaching the shielding to the circuit board. This step also involves making sure that there are no gaps or potential interference that could reduce the shielding's effectiveness.

03

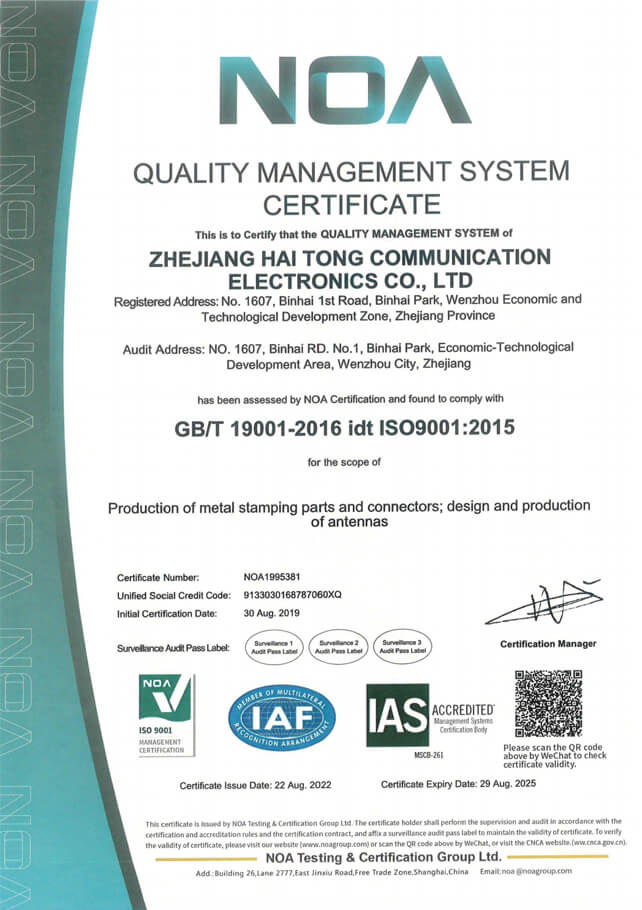

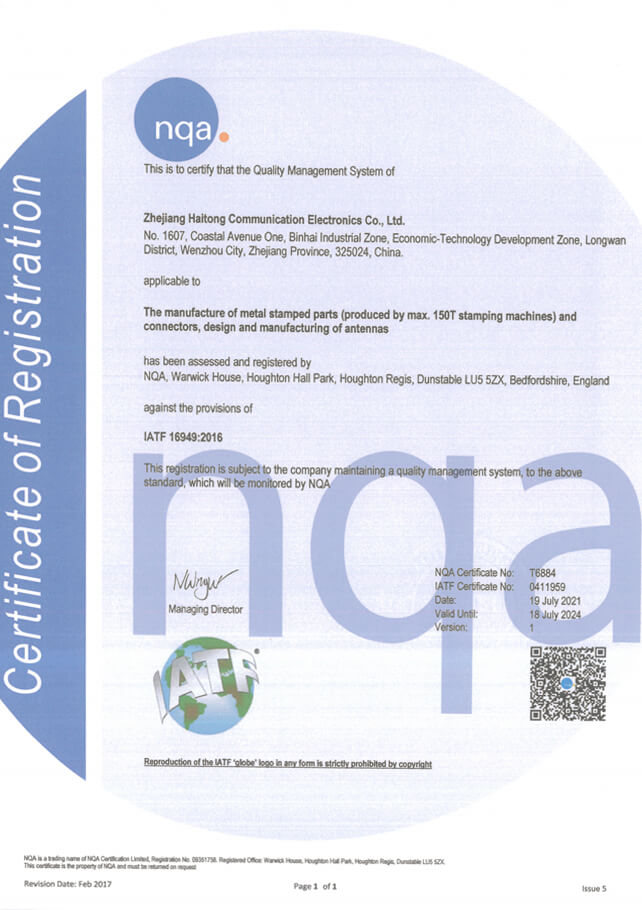

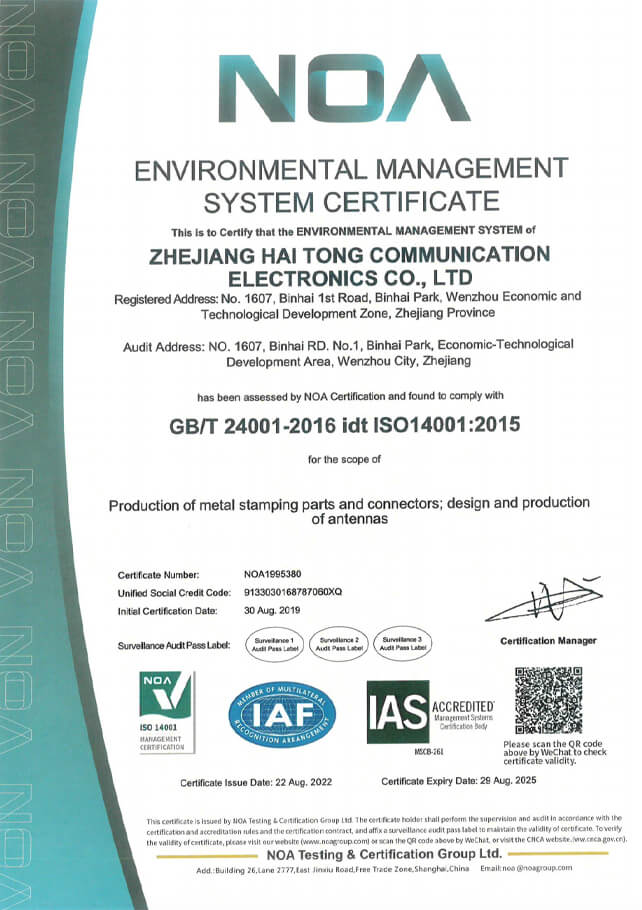

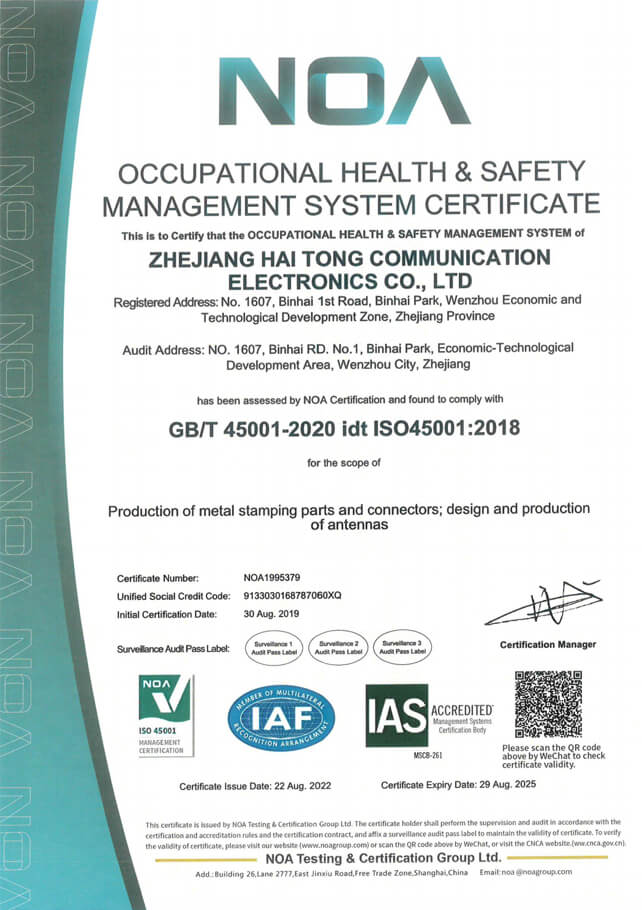

Our certification

As a leading manufacturer of PCB emi shields, we take great pride in our certification, which guarantees the dependability and effectiveness of our products.

Our certification proves our commitment to quality while assuring customers that our rf shield cans solutions comply with the most critical industry standards. The NOA’s criteria have been satisfied.

Why Choose Us

Active customer support

To our customers, we provide round-the-clock customer assistance.

Industrial awareness

Our specialists will lead you through the procedure while offering insightful advice and selecting the best solutions to meet your shielding needs. With years of expertise and an extensive understanding of EMI shielding, they can help.

Superior EMI Safety

Our electromagnetic interference (EMI) shielding solutions offer superior EMI safety, protecting your fragile electronic gadgets from unauthorised interference and retaining their top operation.

Increased Device Protection

Shielding solutions protect delicate electronics from outside electromagnetic fields, lowering the chance of failures, shocks, or other possible risks to consumers.

Extended Device Lifespan

EMI shielding extends the operational life of electronics and minimises warranty costs by eliminating early component breakdowns brought on by electromagnetic interference.

Cost-Effective

Making an initial investment in EMI shielding solutions can save money over time by avoiding costly redesigns, recalled items, or warranty claims brought on by electromagnetic interference problems.