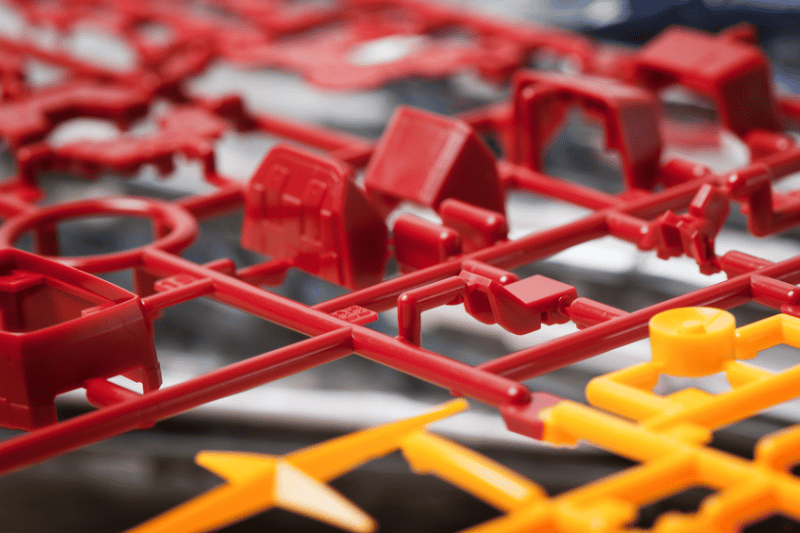

Plastic Injection Mould Tooling

Nhait is a top supplier of plastic injection mould tooling solutions with a focus on the creation, production, and delivery of premium moulds for a range of industries.

With a dedication to accuracy and innovation, Nhait works to provide clients with a range of demands with cost-effective and efficient solutions.

Plastic Injection Mould Tooling Capabilities

WHAT WE DO

Tool Design

When creating an injection mould, tooling also entails creating moulds that can be utilised to develop plastic components. Considerations for tool design include part geometry, material circulation, cooling down and ejection mechanisms.

Mould Supplies

Steel or aluminium are often used to create injection moulds because they are strong and can resist the high heat and pressures involved in the injection moulding process. Although steel moulds are more expensive, they offer better precision and surface polish and can handle more enormous production quantities.

Standards

Steel or aluminium are often used to create injection moulds because they are strong and can resist the high heat and pressures involved in the injection moulding process. Although steel moulds are more expensive, they offer better precision and surface polish and can handle more enormous production quantities.

Exterior Texture

The mould tooling impacts the moulded part's surface finish. To provide the required finish on the finished product, the surface of the mould is frequently polished or textured. On the surface of the part, texturing can create various patterns or textures.

Manufacturing and Prototypes

High-volume manufacturing and prototyping require injection mould tooling. Before investing in more expensive steel moulds for large production, cheaper aluminium or 3D-printed moulds can be used for prototyping.

24/7 Towing Service

24/7 Assistance

Custom Plastic Injection Mould Tooling Solution

WHO WE ARE

To fulfil your unique needs for plastic production, we are pleased to introduce our custom plastic mould tooling solution. We offer effective and affordable solutions using our skills in developing and manufacturing high-quality moulds, assuring accuracy, flexibility, and longevity for your production operations.

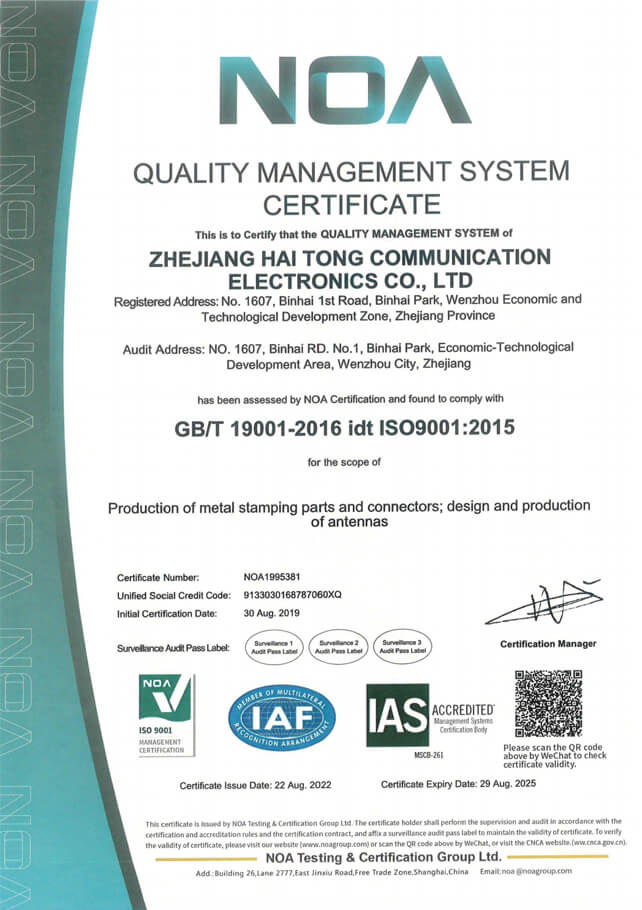

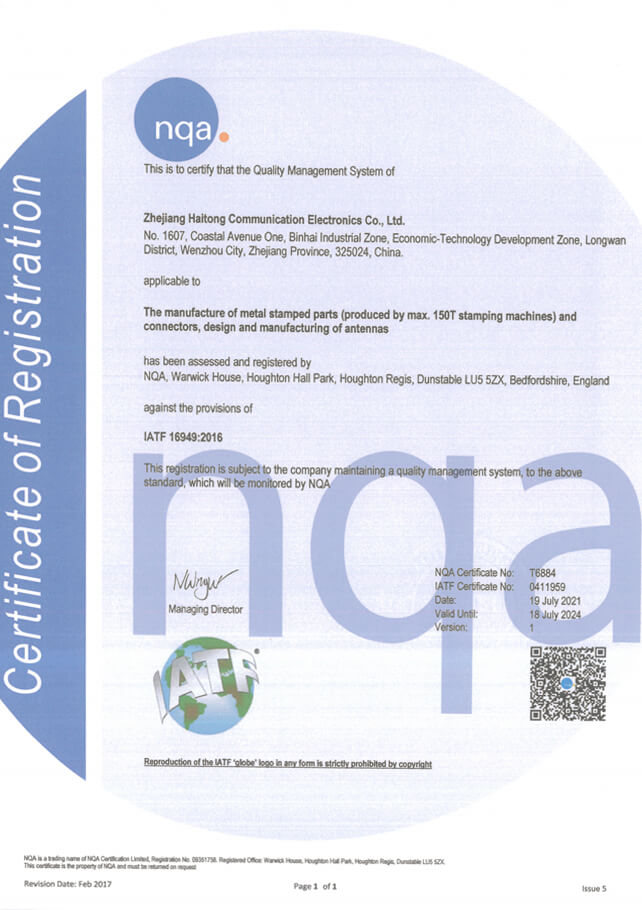

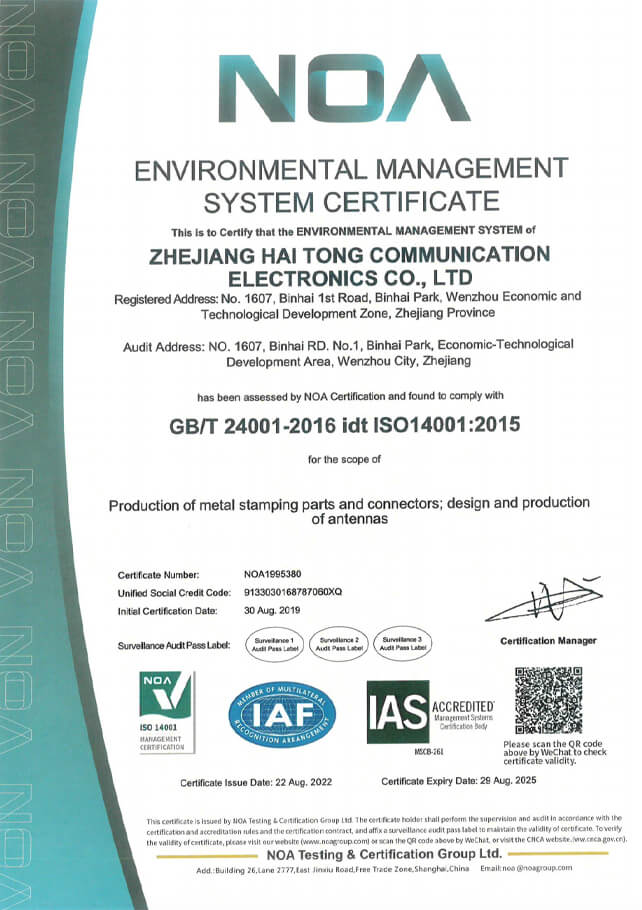

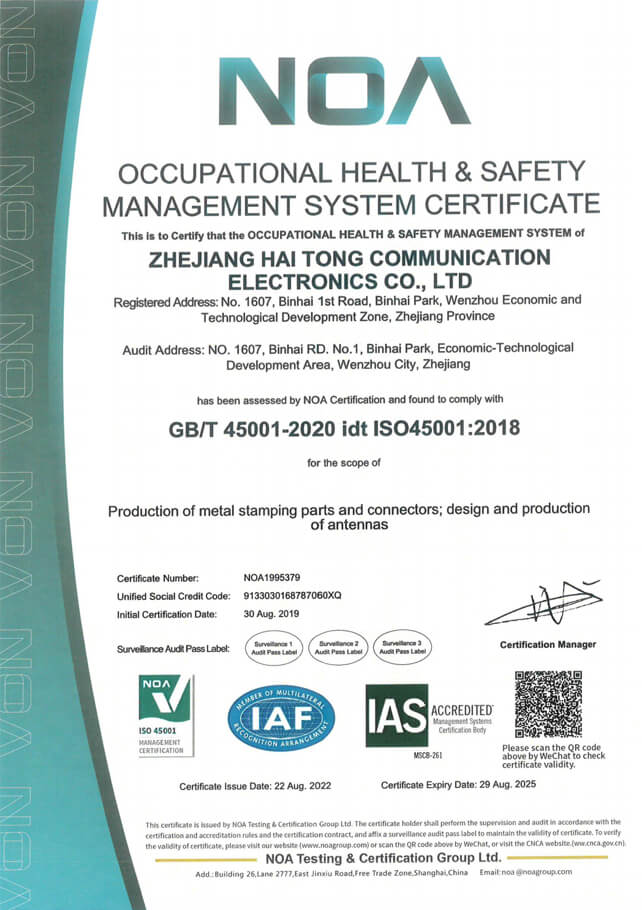

Our certification

process

Application industry and case

WHAT WE DO

Buildings and Constructions

Sports Equipment

Medical Equipment

Electronics Appliances

Industrial Equipment

Experience accuracy and dependability with our plastic injection mould tooling services; get in touch with us right away to bring your ideas to existence!

Why Choose Us

We are pleased to have you visit our manufacturing facility for plastic injection moulding tools. We provide you with great quality and dependability in every facet of our services thanks to our knowledge and experience.

Team of Experts

We have a highly qualified technical professional team committed to providing you with specialised solutions, knowledgeable advice, and on-time delivery of your project.

Affordable Rates

We provide affordable prices without sacrificing quality, giving you cost-effective options that satisfy your financial requirements while upholding the highest standards.

Modern Machines and Software

We use state-of-the-art equipment and software to ensure accurate and effective manufacture of plastic injection mould tooling, resulting in superior outcomes.

Vast Knowledge

We have years of industry experience and have successfully met a variety of customer requirements, which enables us to manage challenging projects and consistently provide excellence.

If you require additional information about our stamping services, please don’t hesitate to contact us. We understand the significance of finding the perfect solution for your application and are more than happy to provide you with all the necessary details you need. Reach out to us today and let us assist you in making an informed decision.

Sales Support

Comprehensive customer support from order placement to post-sale services. Trust Nhait for exceptional service throughout your journey.

Sample Test

Sample delivery within 20-30 days. Mass manufacturing completion expected in 10-20 days. Trust Nhait for prompt and efficient production.

Custom Solution

Custom solutions for stamping services. Advanced machinery and latest production methodology. Trust our expertise for exceptional results.