Spring Contact Manufacturer

Nhait is one of the best industry-accredited spring contacts in the world, and our team is dedicated to providing customer-focused, bespoke services, no matter what you need.

Our wide range of industries has given us the knowledge and experience to meet all customer requirements using our excellent manufacturing techniques, latest machinery, and expertise. Get in touch today, and we’ll deliver the springs you need.

Spring Contact Technology

To fulfill the needs of modern test and measurement issues, Nhait has the growing performance requirements of automated test equipment and test fixtures that necessitate more advanced contact solutions.

Material, manufacturing technology, design, and rapid prototyping advancements have created novel spring contact designs for high-reliability connector assemblies, which provide great options for temporary connections in OEM and test applications.

Great performance, high-class service

WHAT WE DO

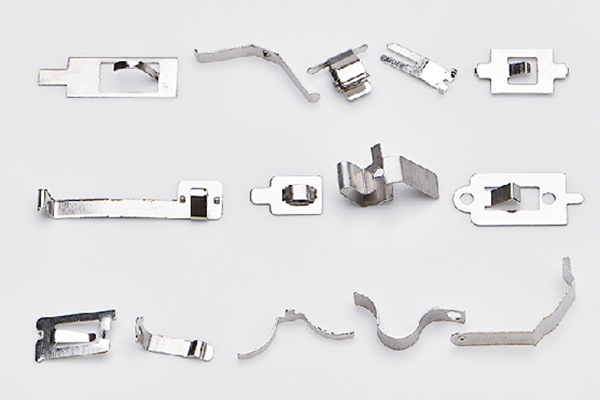

Standard-flat Contact

Application

Pre-loaded Contact

Application

Ultra-small Contact

Application

24/7 Towing Service

24/7 Assistance

Custom OEM Spring Contact Solution

WHO WE ARE

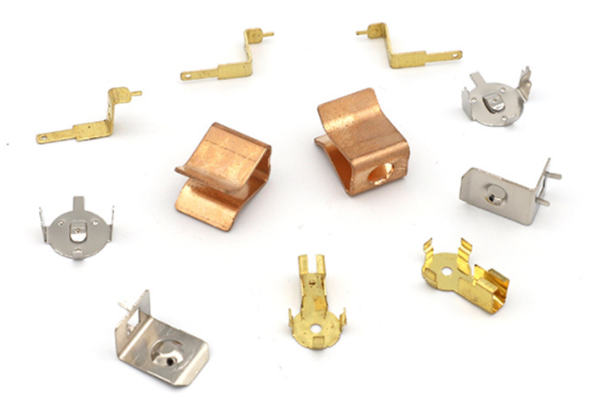

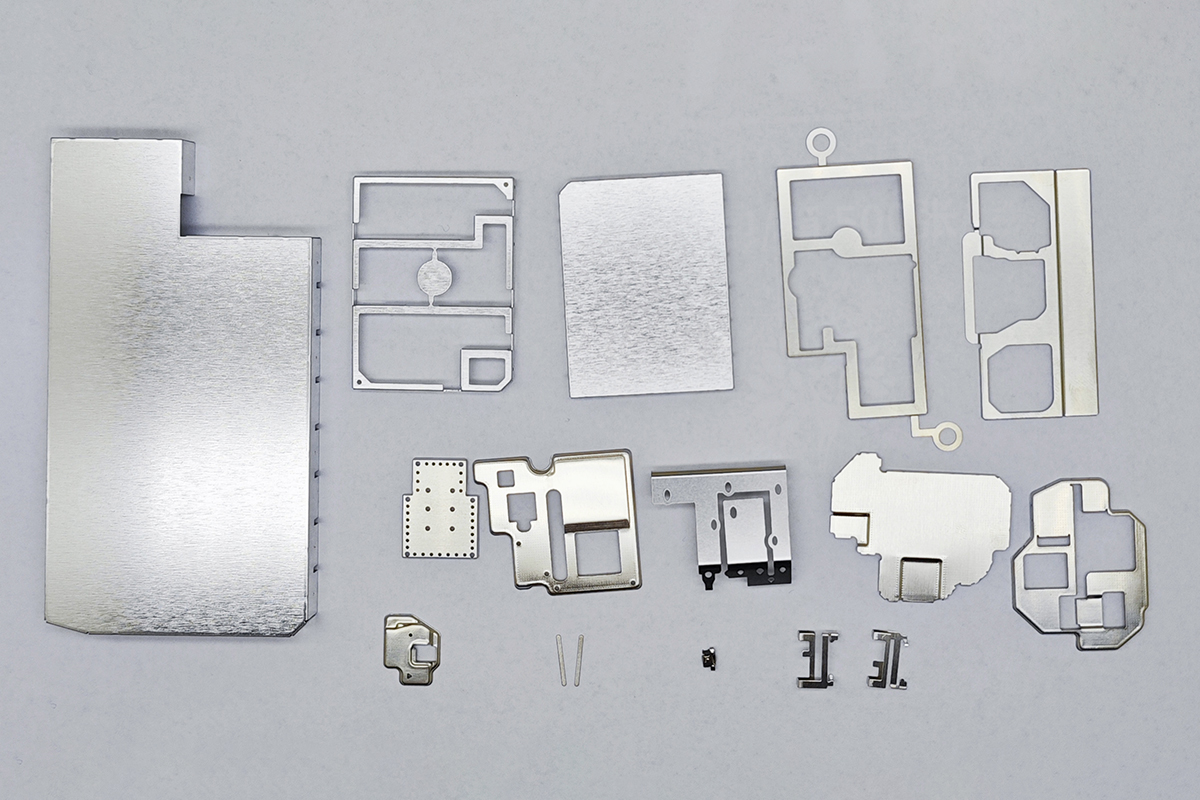

We are an OEM professional manufacturer of spring contacts. With over a decade of spring contact expertise and R&D department assistance, we are always developing our abilities to handle client difficulties. We provide manufacturing services for bespoke metal, battery, spring, and electrical contacts.

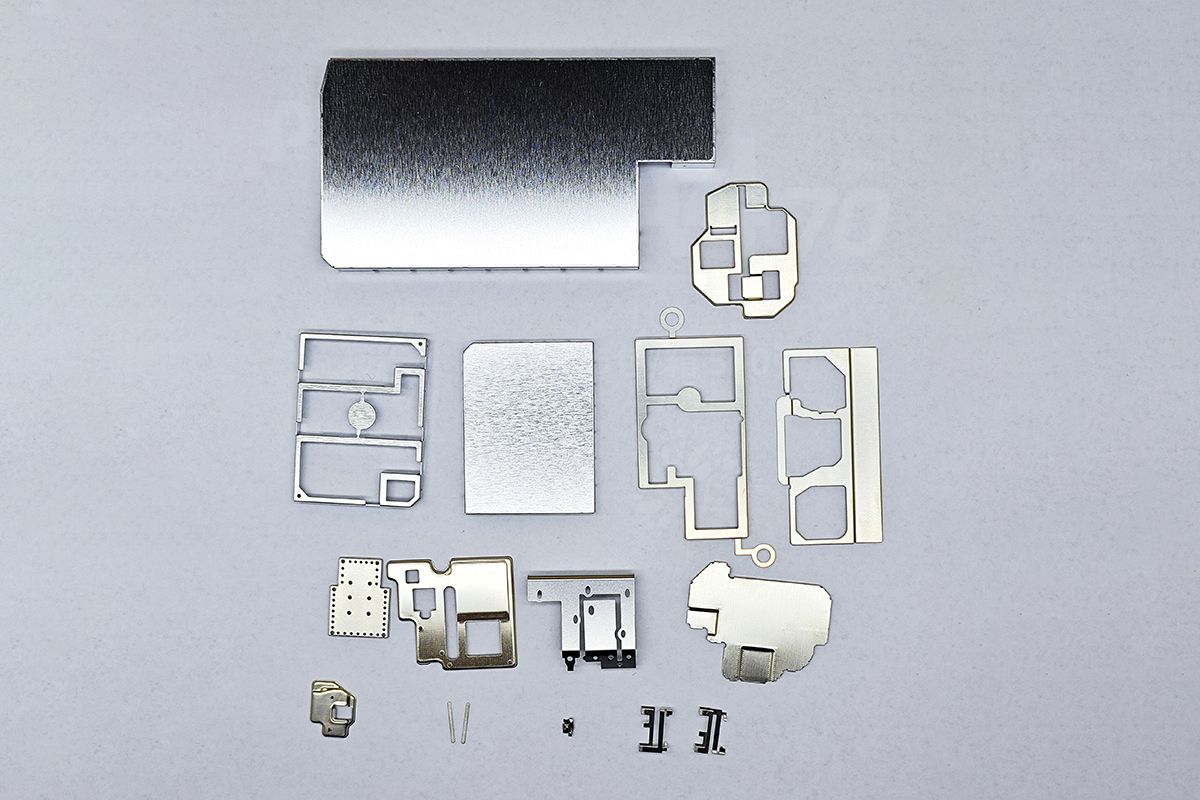

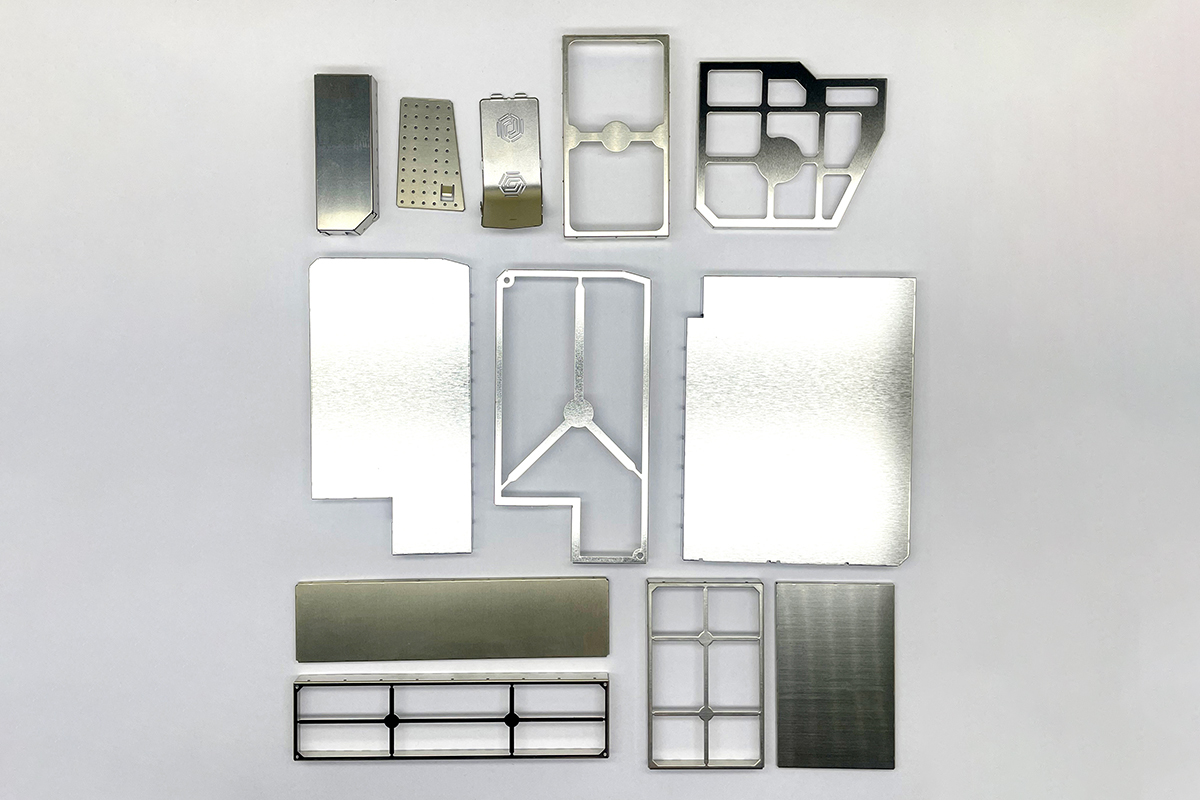

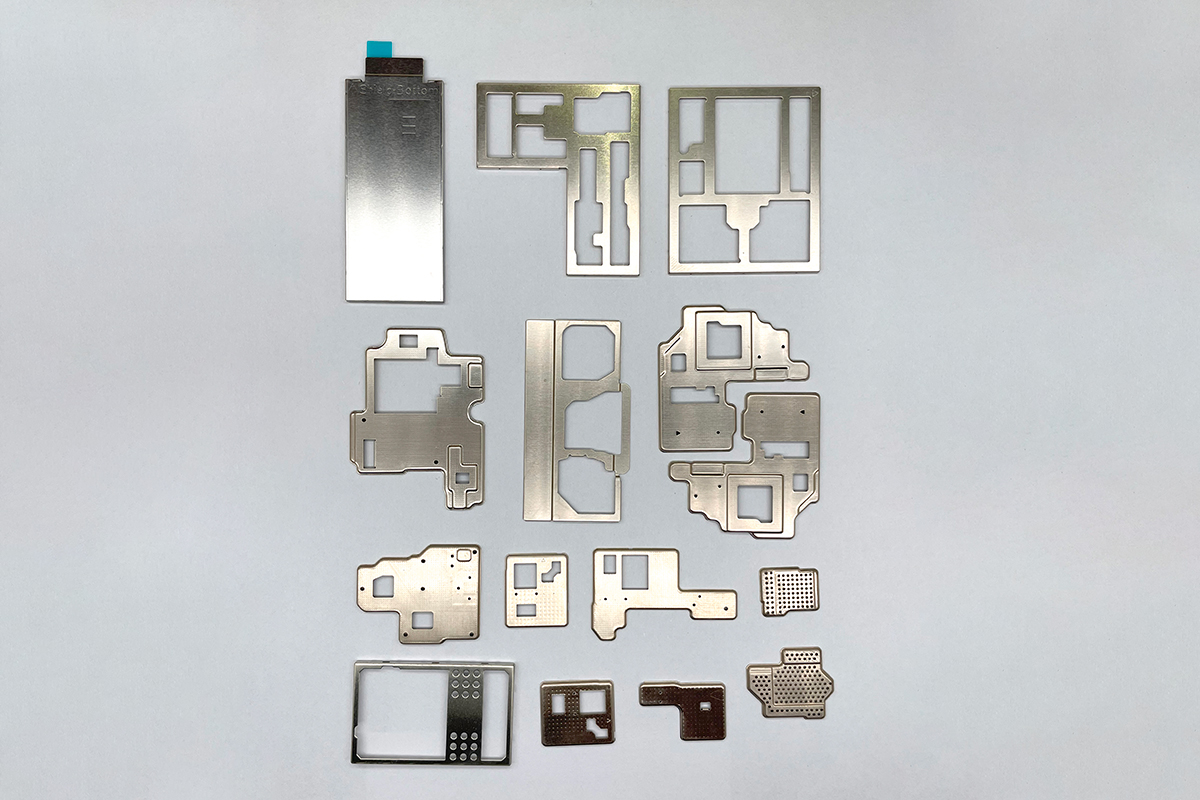

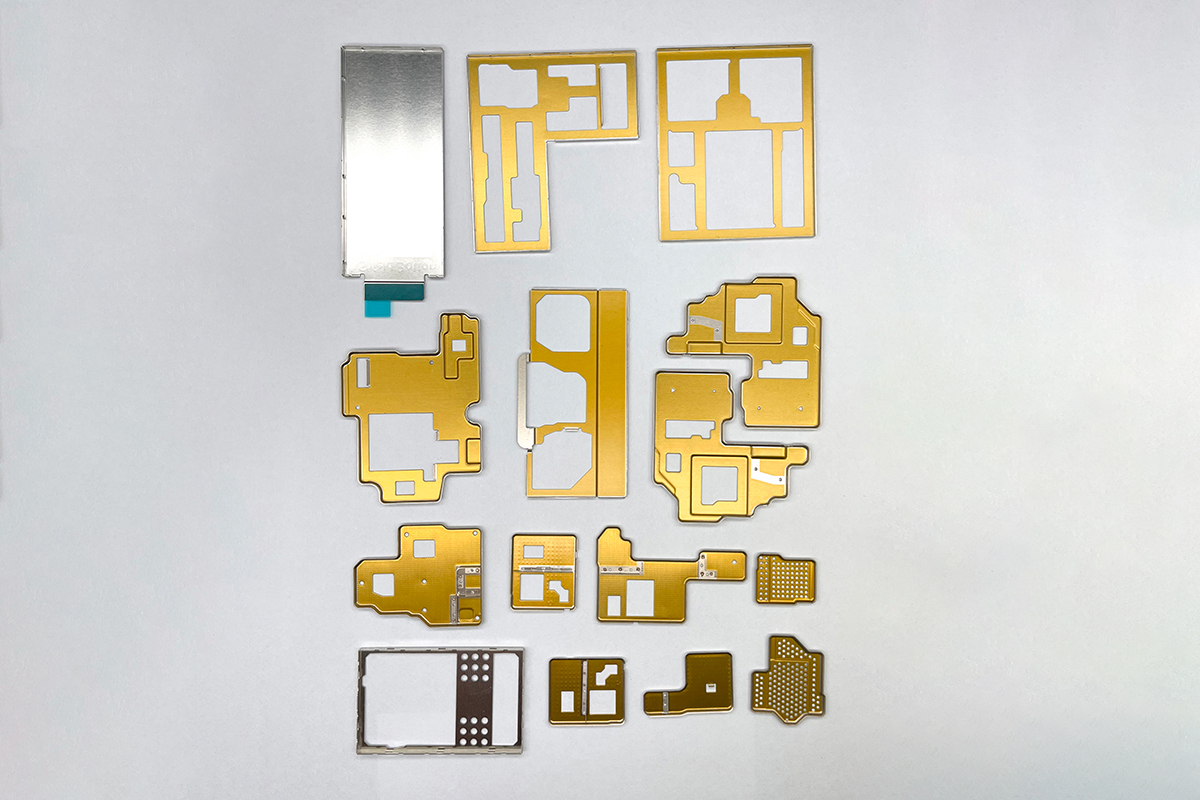

Process in design and production stage for Spring Contact

Although many goods rely on the endurance of their spring components, choosing high-quality spring contact that will not fail early is critical. We in Nhait conservatively follow standard production methodology such as follows:

01

Confirm the application

We design the corresponding size and technical specifications according to the customer's requirements.

Mold design

According to product specifications and material characteristics, our mold workshop will make corresponding molds.

02

Production

According to different products, we have stamping machines of corresponding specifications to produce.

03

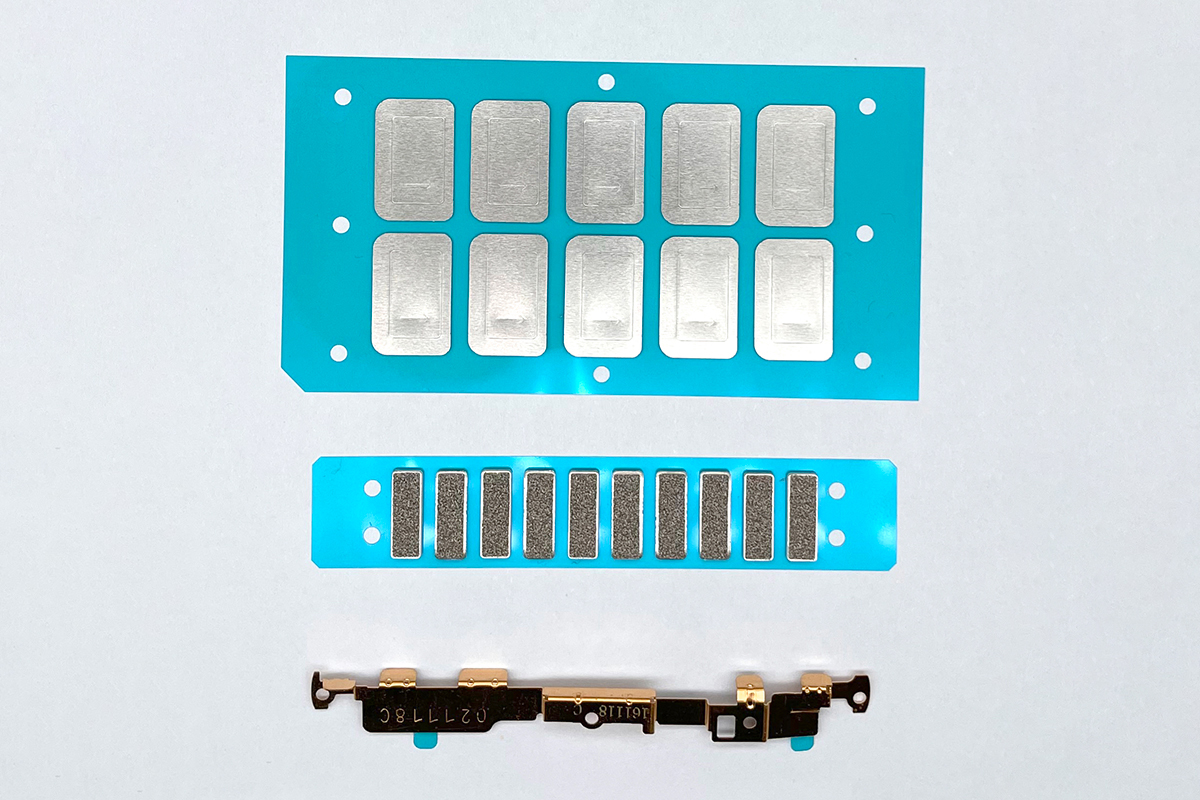

Packaging

According to the customer's requirements, we can provide different specifications of packaging methods such as carrier belt, blister, PE bag, etc

04

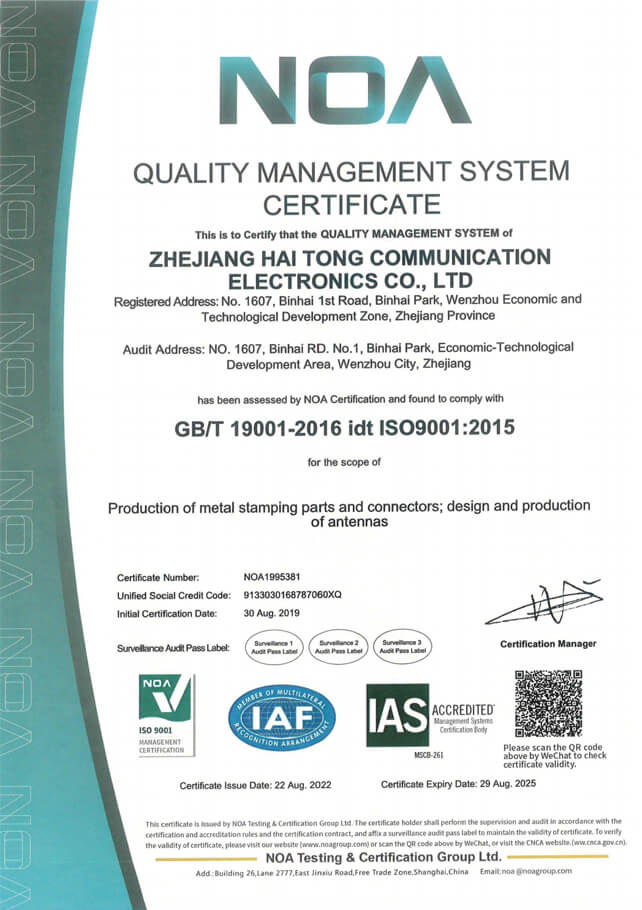

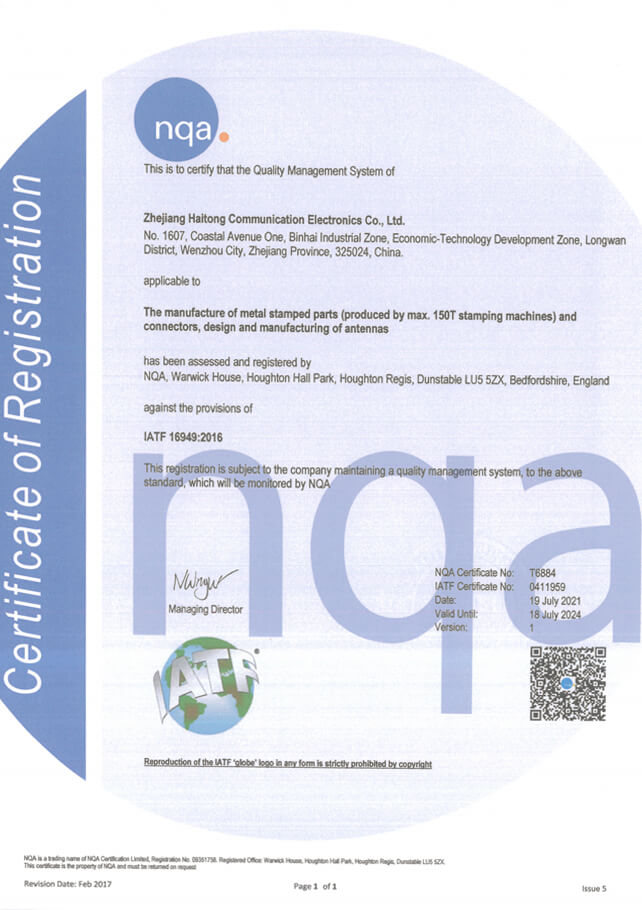

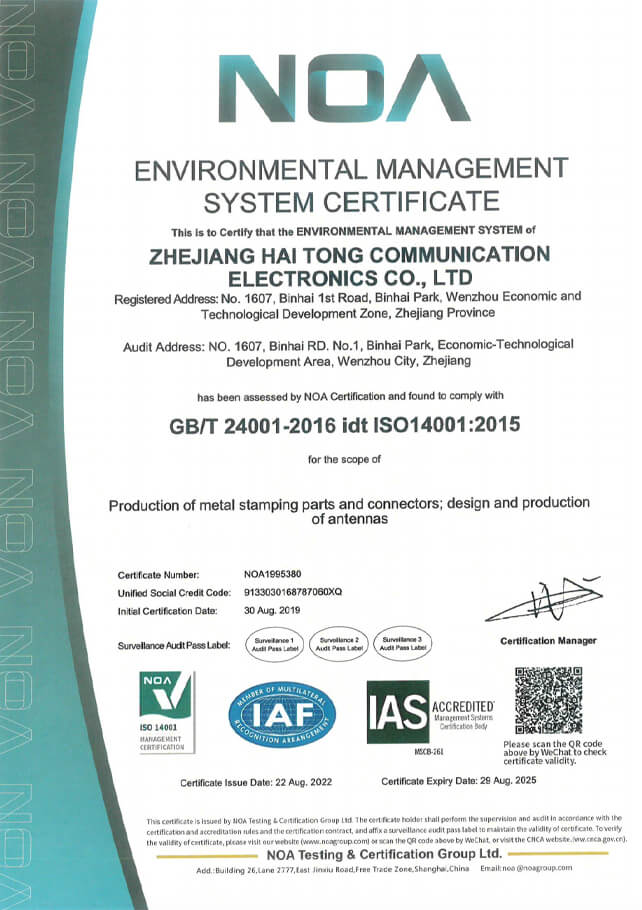

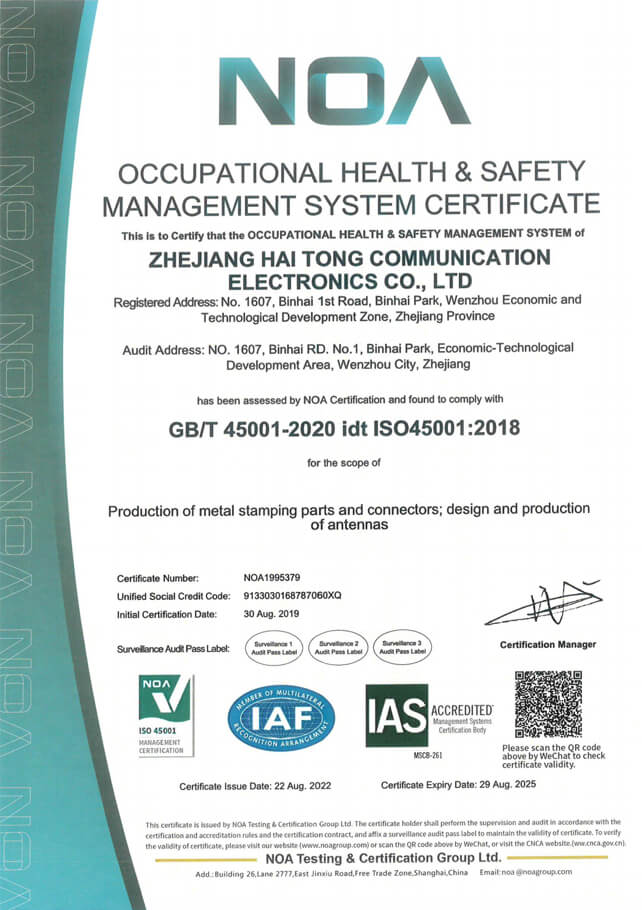

Our certification

process

Why Choose Us

Nhait works hard to enhance the quality and service that our clients expect from a spring contact. Our goods are tested before and during manufacture to guarantee that they meet your expectations.

Committed to your Success

We're here to help, from the quality components we make and the speed with which we make them to an expert staff that can help you solve your most critical technical difficulties.

Quality Without Compromise

Nhait has the experience, ability, and dedication to supplying customized components to satisfy your exact demands, whether you require a single prototype or a multi-million-part production run.

Save your Costs

We offer free tooling design, tooling costs may be refunded if the target quantity is met. We provide expert answers to our clients and assist with product research.

On-Time Delivery

Share your specifications and receive high-quality spring contacts on time.

successful projects

satisfied customers

R&D personnel

production equipment

monthly capacity

Most Popular Questions

COMMON QUESTIONS

A Spring Contact is an internal connector used in electronic devices to provide electrical connection or grounding. Antenna contacts, spring fingers, shield fingers, and grounding contacts are other names for them.

The production of spring finger contacts begins with thousands of meters of Copper Beryllium metal strips (the raw material for the core of the spring contact).

Spring contacts are ideal for making low-voltage electrical connections on various printed circuit boards PCB spring contacts. They are simple to use. Spring contacts can be used for antenna feeding, grounding, EMI noise, and static electricity prevention.

Spring contacts can be employed in a variety of settings and combinations. The electrical spring contact connection is created vertically or laterally on the PCB, depending on the shape and design of the spring contact.

The thickness of the CuBe strip used to make these pieces is 0.08 or 0.10mm. Our primary spring finger contact has a maximum height of 13mm. Some special spring contacts may be installed below this side.

For EMI shielding and grounding, spring contacts are an alternative to EMI Gaskets (Spring Loaded Contact Silicone or Metallic Gaskets). These spring contacts serve as connectors as well. Spring contacts have been designed for a high-efficiency production process.

Our experts will answer any questions for you, click the button to contact us!

Why They Trust Us

TESTIMONIAL

Our clients

Need help finding what you’re looking for? Please contact us if you have any questions, and our team will be pleased to assist you.

Sales Support

At Nhait, we focus on our client's requirements and desires by providing full-service customer assistance from order placement through shipment and post-sale services.

Sample Test

We will provide the customer samples within 20-30 days of receiving their order. We anticipate completing mass production in 10-20 days.

Custom Solution

We offer a one-of-a-kind solution for all stamping services our customers require with our cutting-edge machinery and production methods.