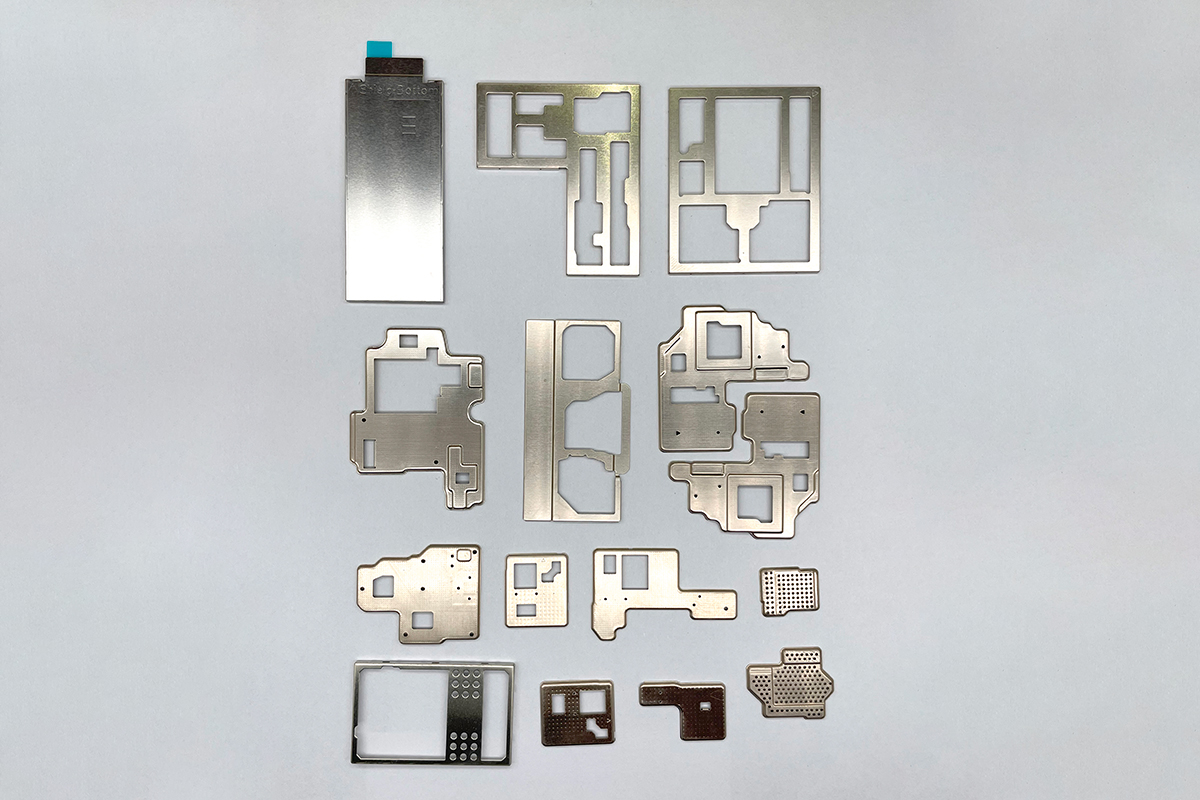

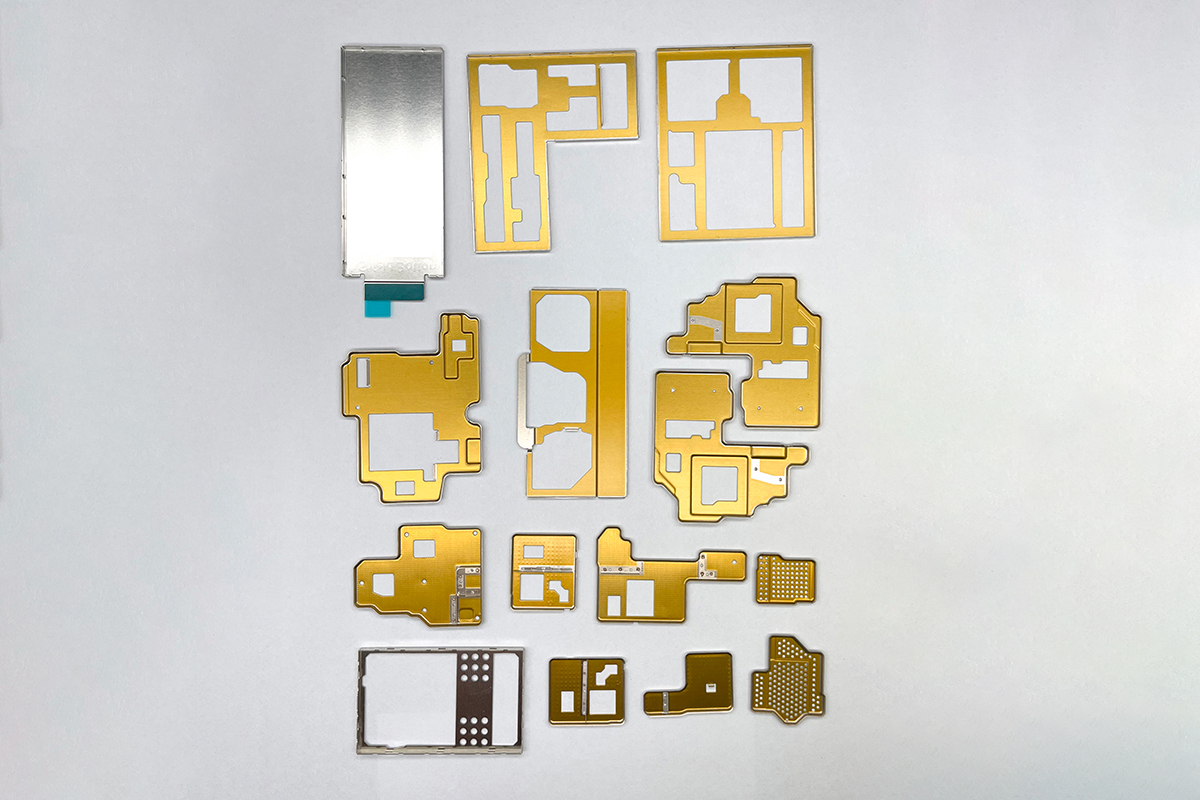

Stamping Parts Manufacturer

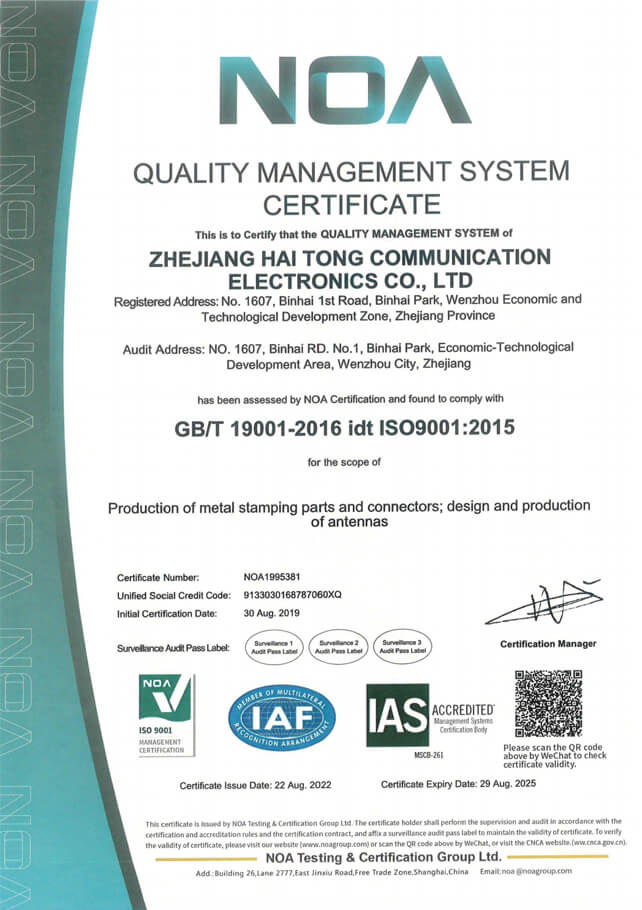

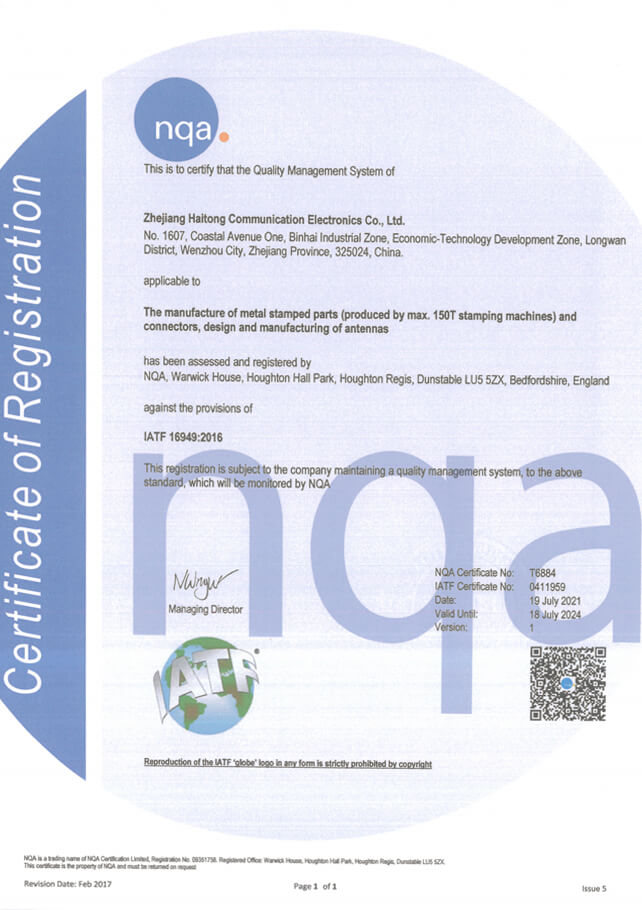

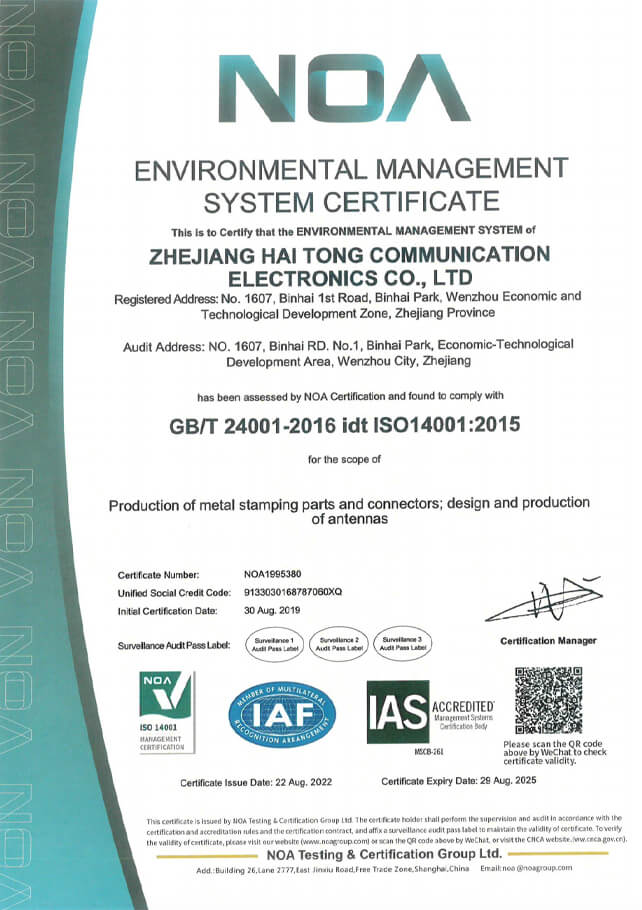

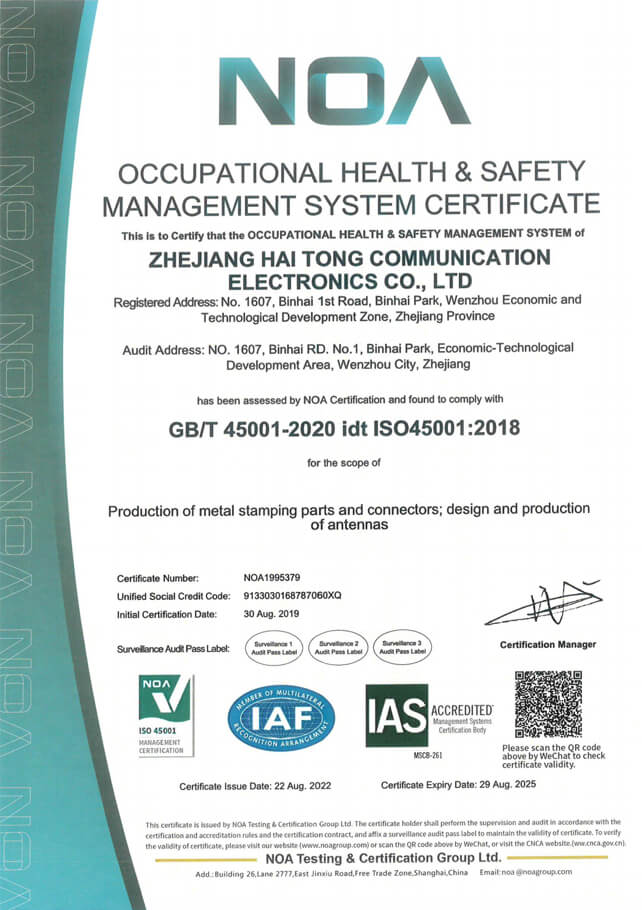

Are you searching for a stamping parts manufacturer for your company? Nhait has metal stamping parts manufacturer experts. We have over 20 years of experience creating customized solutions for our customers in various industries. We are fully ISO, IATF certified and bring a high-quality commitment to everything we do.

Which of our processes can satisfy you

WHAT WE DO

Automotive Stamping

Application

CED Coated Automotive Stamping

Application

Powder Coated Automotive Stamping

Application

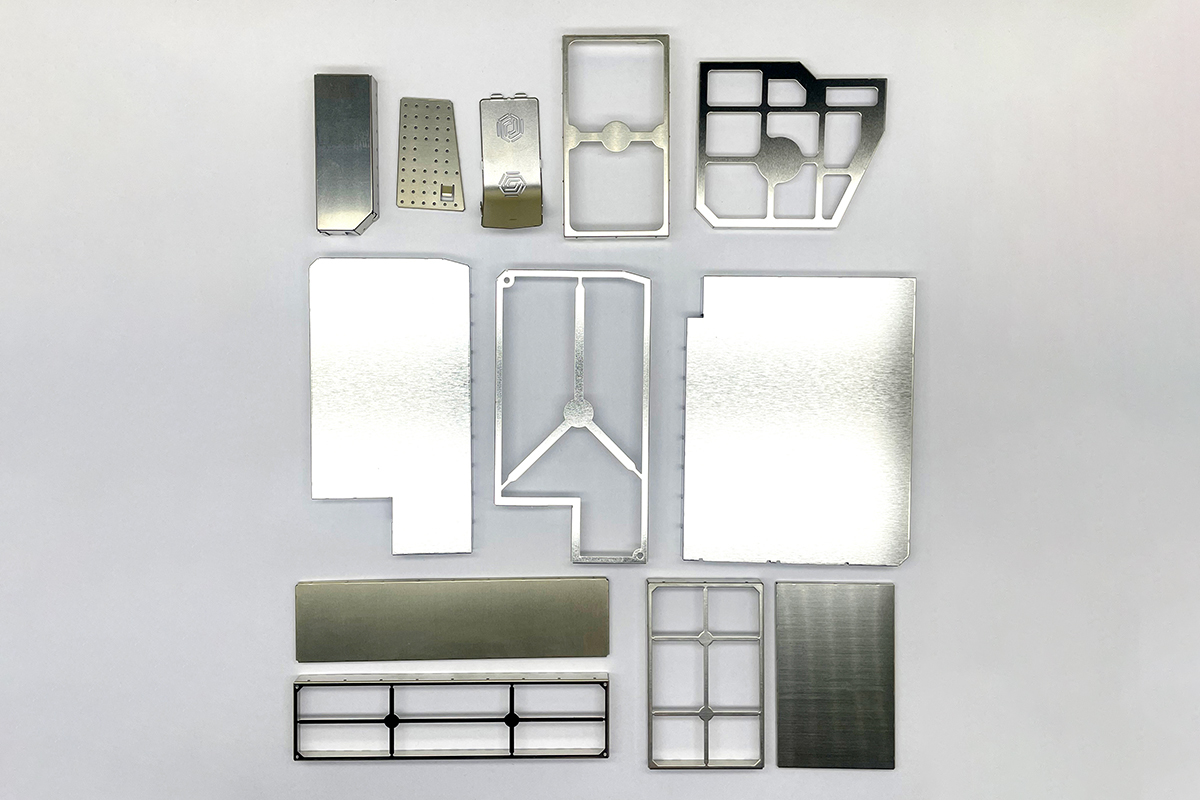

Progressive Stamping

Application

Four Slide Stamping

Application

Fine Blanking

Application

24/7 Towing Service

24/7 Assistance

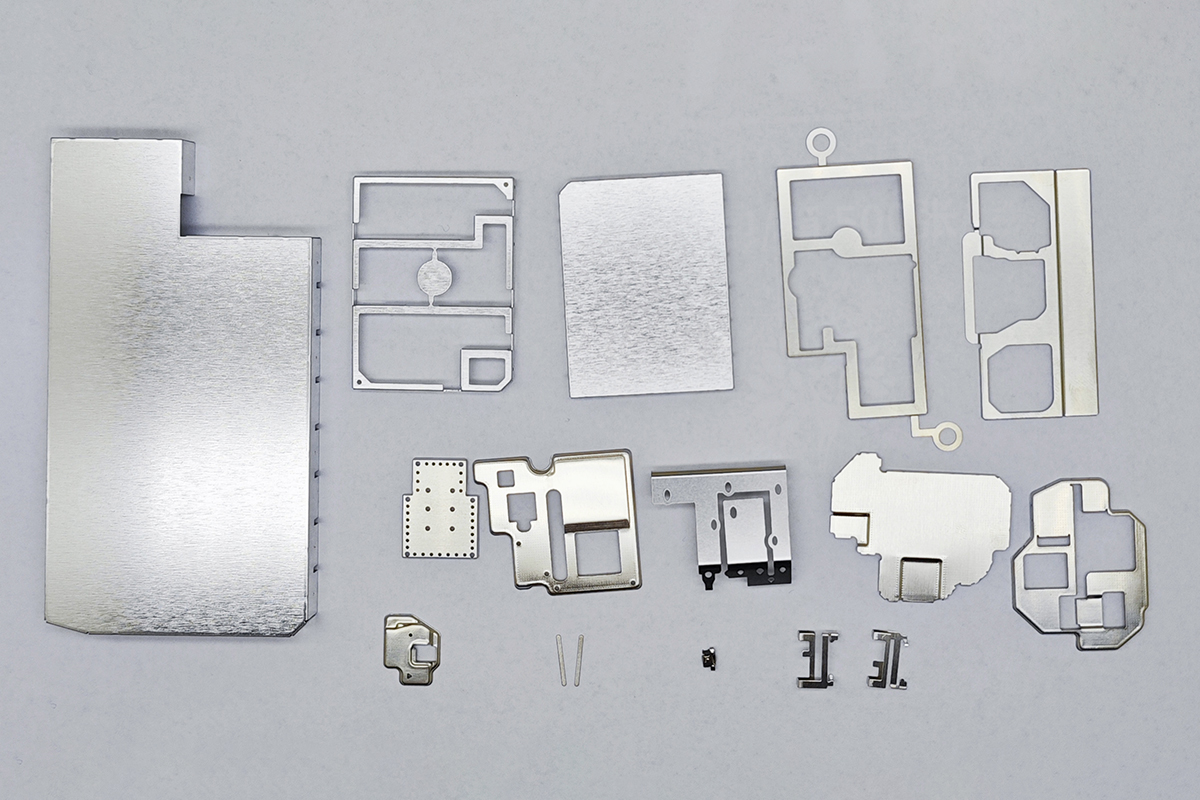

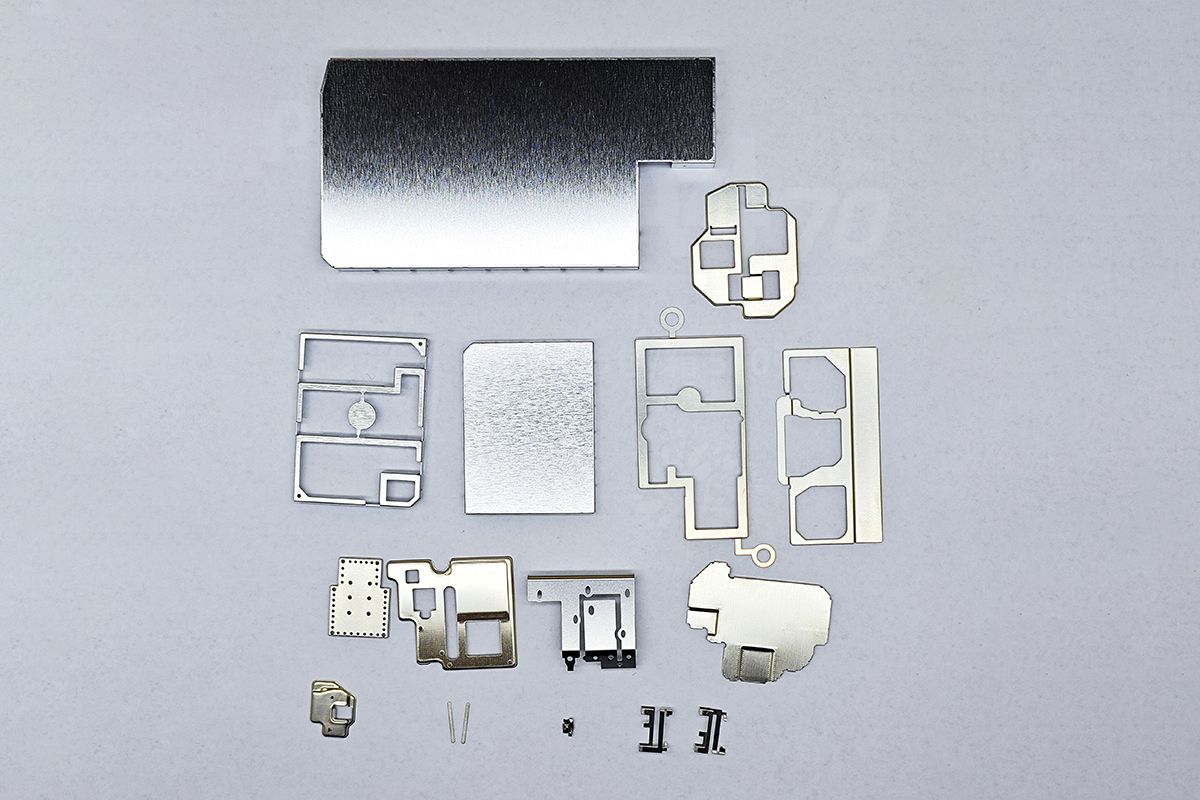

Custom OEM Stamping Parts Solution

WHO WE ARE

Nhait manufactures entirely personalized items. Furthermore, materials, equipment, and techniques can be modified during manufacturing. Rapidly and affordably test and enhance your stamped component design. We provide cost-effective solutions for high-volume components while maintaining quick lead times.

Which materials can be selected

While more complex stamping equipment can produce high-quality components, selecting the correct raw materials is just as crucial as selecting the suitable machining method. In stamping, many raw materials are typically utilized.

Copper Alloys

Copper is a pure metal that may be stamped into many different pieces, but it is also valuable in alloys. Copper alloys contain a variety of metals, such as brass, bronze, nickel, silver, and others. Because of its adaptability, copper and its alloys are among the finest materials for stamping.

Steel Alloys

Steel is a metal alloy that consists of iron and carbon. It is one of the most often used raw materials in metal stamping and comes in various variants, each with unique properties.

Aluminum Alloys

Aluminum is a light material, and its alloys are the same. Because of their small weight, the metals are perfect for constructions that demand strength without added burden and applications at remote locations that require transportation. They do, however, have their distinct features and ideal uses.

Specialty Metals

Specialty metals are a diverse group of materials designed to survive harsh and severe conditions without rusting, deteriorating, or becoming brittle. Many titanium or nickel-based alloys fall within this group.

Our certification

process

Application industry and case

WHAT WE DO

Aerospace industry

Automotive Industry

Construction industry

Hospitality and Food Service Industry

Shipping and Transportation Industry

Medical and Defense Industry

Our experts will answer any questions for you, click the button to contact us!

Why Choose Us

We are already in our decade year of service as a premier stamping parts provider. We provide several types of stamping. Our plans to expand and scale our manufacturing plant over the next few years will enable us to continue producing at a high level.

Competitive Price

We can provide cost-effective solutions for a wide range of businesses.

In-house Tooling and Prototyping

Short lead times with high-quality assurance. Easily modify your design.

On-Time Production

With 43 modern stamping machines ranging from 10 to 80 tons, we are widely recognized in many regions.

Nondisclosure Agreement

Pledge to secure all of your information.

Most Popular Questions

COMMON QUESTIONS

Yes, we can keep up with the pace. Tooling speed is proportional to a component structure. To achieve consistent production, we must consider strip thickness and bending stations and give a reasonable rate.

1. Raw materials are obtained from a reputable provider, and quality is assured.

2. The surface treatment will be carried out using a qualified provider.

3. Nhait management process is used for supplier control.

4. Internal SOPs carefully govern production.

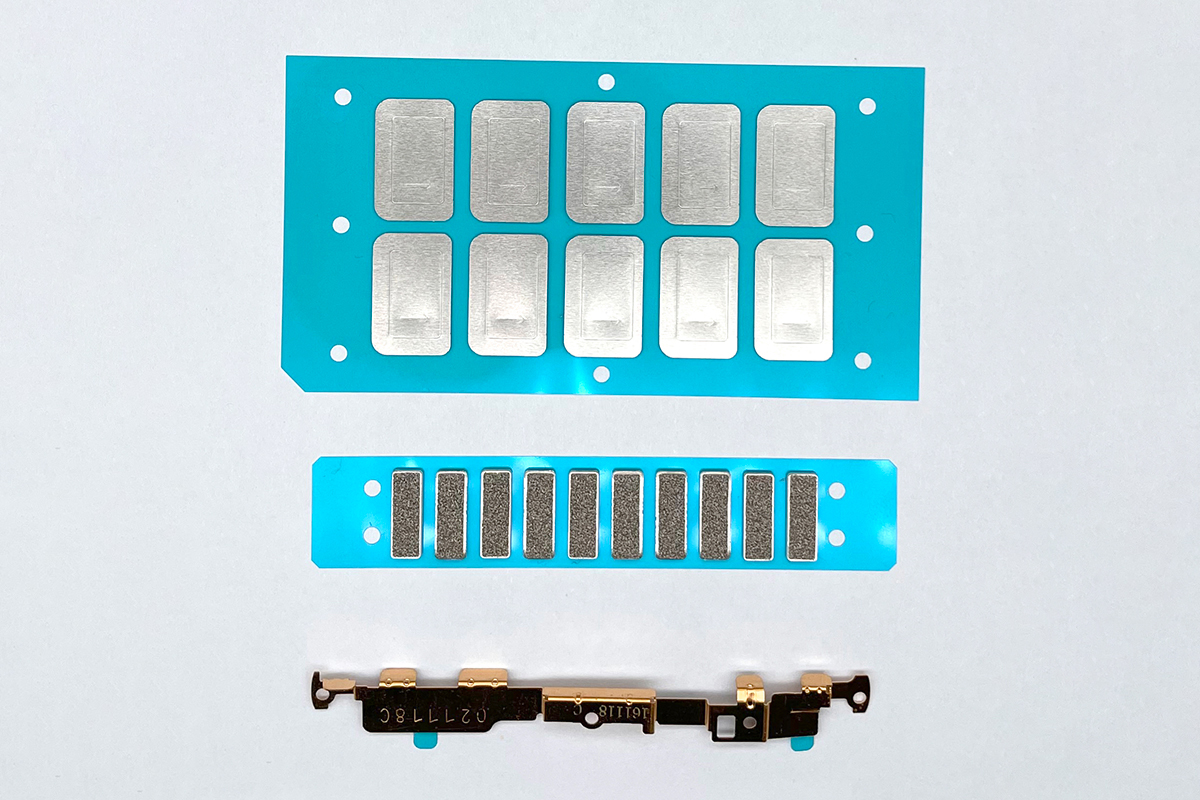

The stamping process is extensive and complex. Stamping is inserting flat sheet metal into a stamping press, either in coil or sheet form. A tool and die surface mold the metal into the required shape in the media. Stamping techniques used to form metal include punching, blanking, bending, coining, embossing, and flanging.

Steel, stainless steel, copper, brass, nickel, and aluminum are common stamping alloys. Exotic materials like Inconel and Kovar, on the other hand, may be better suited for specialist and demanding applications.

Stamping, often known as pressing, is the process of inserting flat sheet metal into a stamping press, either in coil or blank form. A tool and die surface mold the metal into the required shape in the media. Stamping techniques used to form metal include punching, blanking, bending, coining, embossing, and flanging.

Metal stamping is a highly automated process that produces exceedingly accurate items with astounding precision. This enables exact standards to be met in large quantities. This is due greatly to stamping simulation technology, which we’ve already discussed.

Our experts will answer any questions for you, click the button to contact us!

Why They Trust Us

TESTIMONIAL

Our clients

Please contact us if you want any further information about our stamping services. We realize how important it is to discover the perfect solution for your application and will gladly offer you all of the essential information.

Sales Support

Here at Nhait, we prioritize customers' needs and requests by giving them full-scaled customer support from placing their orders to shipment and post-sale services.

Sample Test

We will provide samples to the customer within 20-30 days of receiving their purchase. We expect to complete mass manufacturing in 10-20 days.

Custom Solution

We provide a custom solution for all stamping services needed by our customers. With our advanced machinery and latest production methodology.